| Tweet |

Custom Search

|

|

|

||

3500 ENGINE

SPECIFICATIONS

WATER PUMP

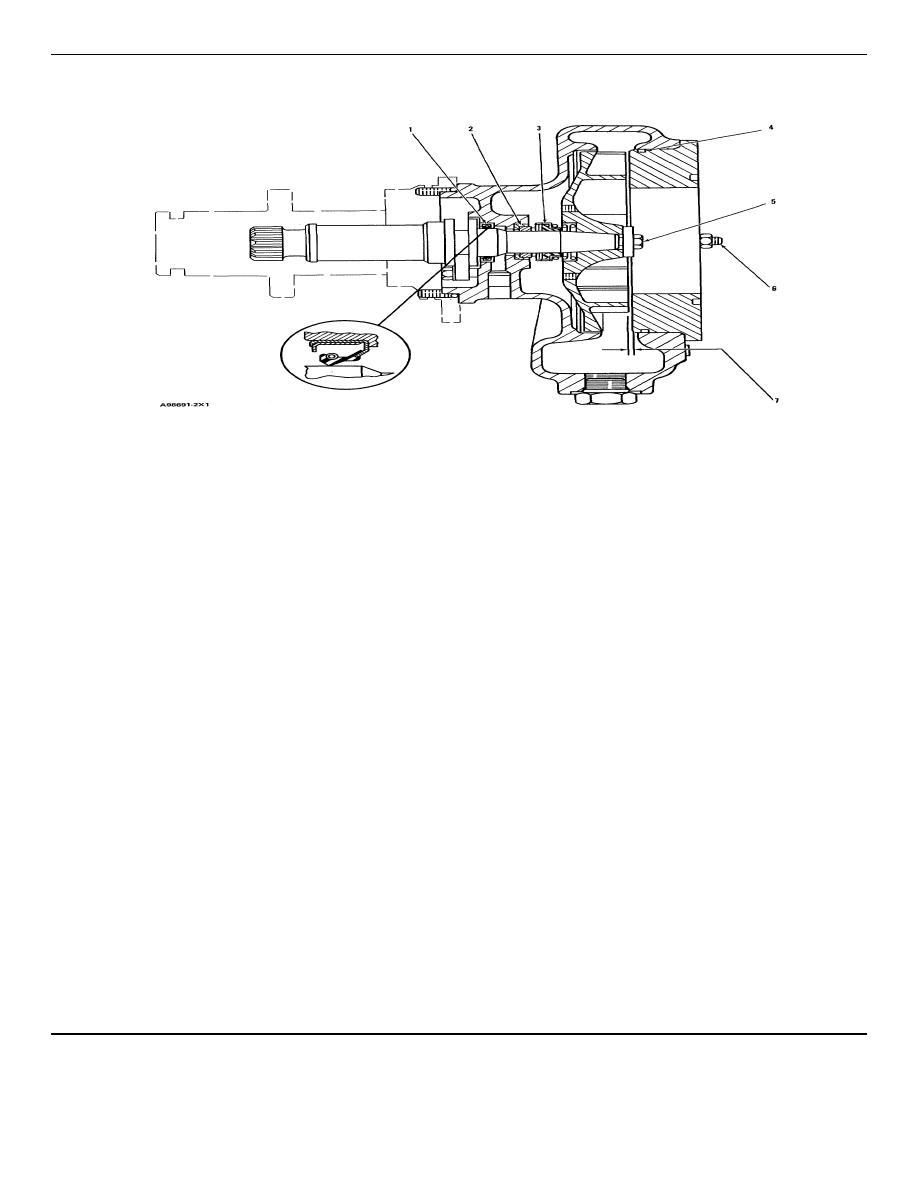

EARLIER WATER PUMP ILLUSTRATED

(1)

Oil seal. Put glycerin or clean engine oil on the

the bore for the seal.

lip of the seal. Assemble with the lip toward the

splined end of the pump shaft as shown.

(5)

Earlier water pumps:

(2)

Ceramic ring and rubber water seal.

Torque for bolt that holds

impeller ........90 15 Nm (65 11 lb. ft.)

a.

Put clean water on the seal and ring.

Hit bolt with hammer and again

tighten bolt to................. 90 15 Nm (65 11

b.

Use the seal installation tool (part of the

replacement seal assembly) and hand

lb. ft.)

pressure to install the rubber seal and

ceramic ring as a unit in the housing bore.

*Later water pumps:

Make sure the identification groove of the

ceramic ring is installed inside the rubber

Torque for nut that holds

seal.

impeller ........200 25 Nm (150 18 lb. ft.)

(3)

Seal Assembly:

(6)

Torque for the three studs in pump

housing ........27 4 Nm (20 3 lb. ft.)

a.

Remove the spring from the seal assembly.

(7)

Clearance between impeller and cover:

b.

Put clean water inside the seal assembly.

Earlier water pumps ...................... 0.12 to 0.89

c.

Use the seal installation tool (part of the

mm (.005 to .035 in.)

replacement seal assembly) and hand

pressure to install the seal assembly on the

*Later water pumps ...................... 0.62 to 1.39

shaft until the carbon face makes light

mm (.024 to .055 in.)

contact with the shiny face of the ceramic

seal.

*NOTE: Later water pumps have a nut that

holds the impeller on the pump shaft.

d. Install the spring.

(4)

Seal. Put a light amount of clean engine oil in

NOTE: FOR TORQUE VALUES NOT GIVEN, SEE THE FIRST PAGE OF SPECIFICATIONS FOR

GENERAL TIGHTENING TORQUES

31

|

||

|

||