| Tweet |

Custom Search

|

|

|

||

FUEL SYSTEM

SYSTEMS OPERATION

FUEL INJECTOR OPERATION

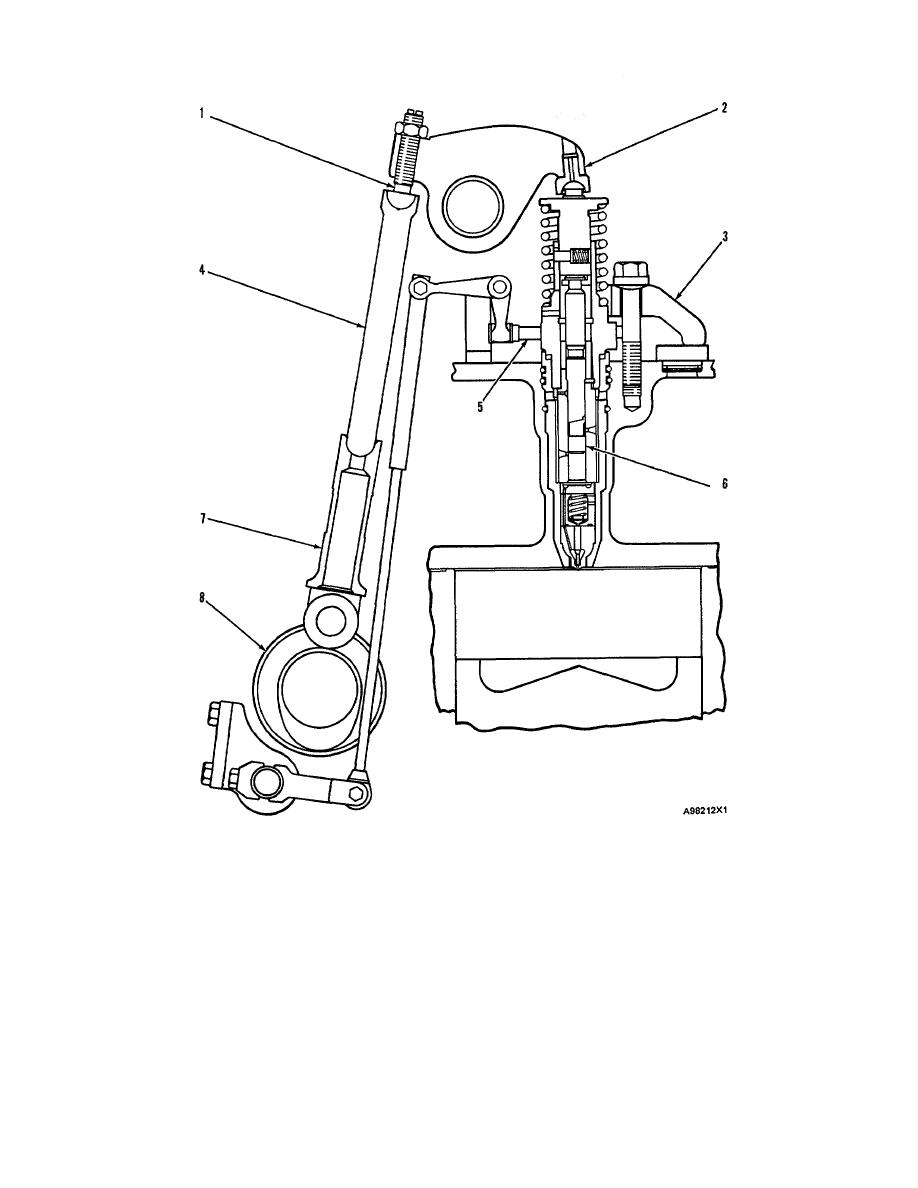

1. Screw. 2. Rocker arm. 3. Clamp. 4. Control rod. 5. Rack. 6. Plunger. 7. Litter assembly. 8. Camshaft.

seat to give line contact.

The valve opens at

A flat check valve is used above the needle

approximately 20 000 to 23 300 kPa (2800 to 3400 psi)

valve to keep the high pressure combustion gases out of

and closes at approximately 10 300 kPa ( 1500 psi). The

the injector. If the needle valve is held open by small

fuel flows from the chamber inside the barrel through

foreign particles for a moment between injection cycles,

drilled passages and grooves in the spring cage, and

combustion gases can come into the injector and cause

then through passages around the guide section of the

damage. The injector operates with the flat check valve

valve to the valve chamber. Here the fuel pressure lifts

until the foreign particle has washed on through and

the needle valve off its seat, and the fuel now flows

normal operation takes place.

through the spray tip and out the orifices into the

combustion chamber.

69

|

||

|

||