| Tweet |

Custom Search

|

|

|

||

FUEL SYSTEM

TESTING AND ADJUSTING

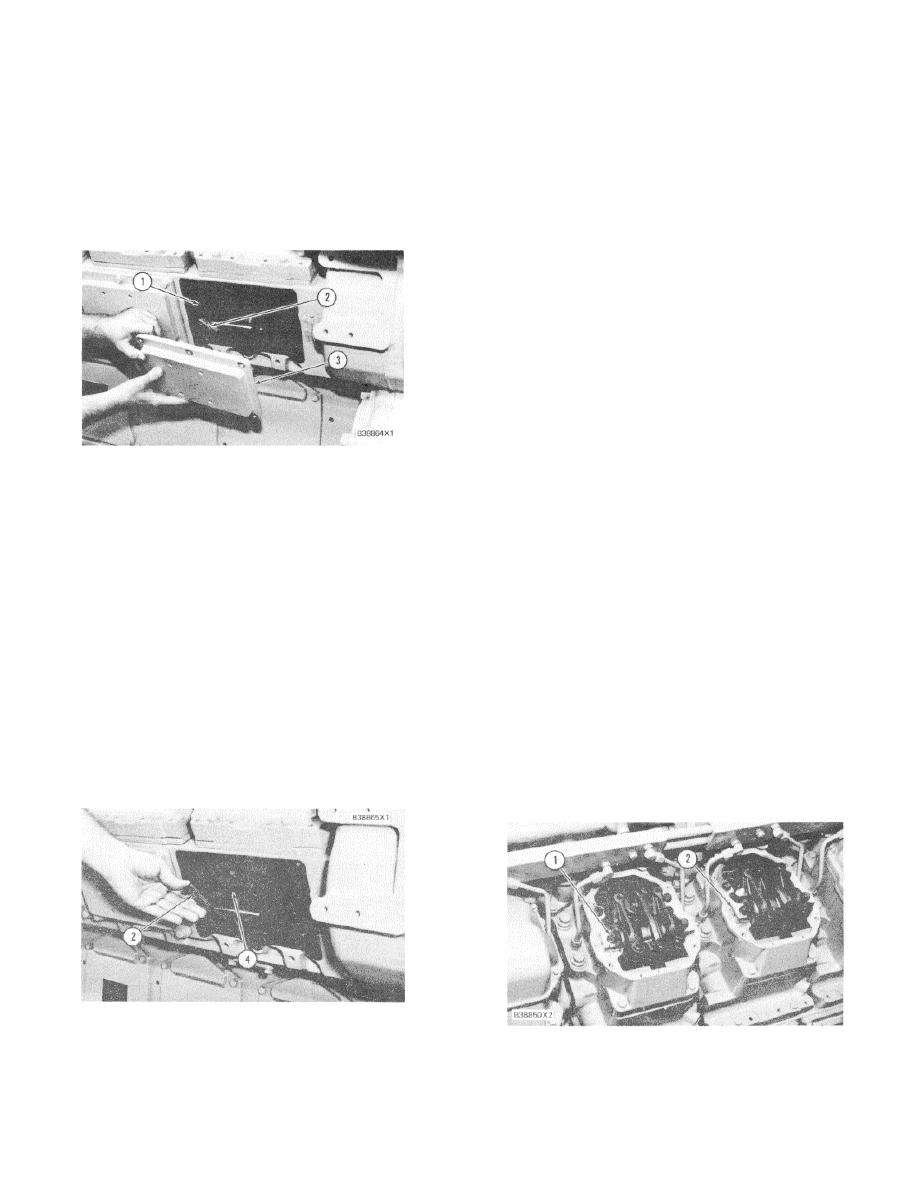

timing pins (2) from their storage positions.

CAMSHAFT TIMING

Timing Check

5.

Install timing pins (2) through holes (1) in the

engine block and into the groove (slot) in

Tools Needed:

camshaft (4) on each side of the engine. For the

9S9082 Engine Turning Tool.

engine to be timed correctly, the timing pins

must fit into the groove of each camshaft.

1.

Remove rear camshaft cover (3) from both sides

of the engine.

6.

If timing pins (2) do not engage in the grooves of

both camshafts, the engine is not in time, and

one or both camshafts must be adjusted.

7.

Both camshafts are adjusted the same way.

See TIMING ADJUSTMENT for the procedure to

put the camshafts in time with the crankshaft.

NOTICE

If a camshaft is out of time more than 18 degrees

(approximately 1/2 the diameter of timing pin out of

groove), the valves can make contact with the

pistons. This will cause damage that will make

1. Timing hole. 2. Timing pin. 3. Cover.

engine repair necessary.

2.

Make reference to FINDING TOP CENTER

Timing Adjustment

POSITION FOR NO. I PISTON.

Tools Needed:

NOTE: Since both rear camshaft covers have to be

9S9082 Engine Turning Tool.

removed to check the timing, it is not necessary to

6V3010 Puller Group.

remove No. 1 valve cover to find the compression stroke

9S9089 Two 1/2 - 13 NC Bolts 114.3 mm (4.50

when timing bolt is installed in flywheel.

in.) long.

5P1076 Two Washers (Hardened).

3.

With timing bolt installed in flywheel, look at rear

of camshaft to see if timing groove (slot) is

NOTE: Before any timing adjustments are made, the

visible on the camshaft. If it is visible, No. 1

timing must be checked first to see if adjustment is

piston is on the compression stroke. If it is not

necessary.

See subject TIMING CHECK for this

visible, feel the backside of the camshaft for the

procedure.

groove. If the groove is at the back of the

camshaft, the flywheel will have to be turned

After TIMING CHECK procedure is complete,

3600 to put No. 1 piston on the compression

timing bolt will be engaged in flywheel with No. 1 piston

stroke.

at top center (TC) position.

INSTALLATION OF TIMING PINS

LOOSEN ROCKER SHAFTS

2. Timing pin. 4. Camshaft (L.H.).

1. Bolt. 2. Rocker shaft.

4.

With timing bolt installed in flywheel with No. 1

piston now on compression stroke, remove

118

|

||

|

||