| Tweet |

Custom Search

|

|

|

||

3161 GOVERNOR

SYSTEMS OPERATION

AIR FUEL RATIO CONTROL

limiter piston and the pressure of the oil starts to

increase. When the oil pressure is high enough, the

limiter piston is pushed down against the limiter servo

spring force. The lower edge of the fuel limiter plunger

opens the port in the limiter piston when the piston has

moved down far enough. This lets supply oil go to drain.

The air fuel ratio control is now activated and can

operate as needed.

Engine Load Increases

As more load is put on the engine, the air

pressure in the inlet manifold is increased.

The

increased air pressure pushes the rolling diaphragm

assembly up and lifts the fuel limiter plunger more. Oil

pressure on the limiter piston decreases as the limiter

piston drain port is opened and the limiter piston moves

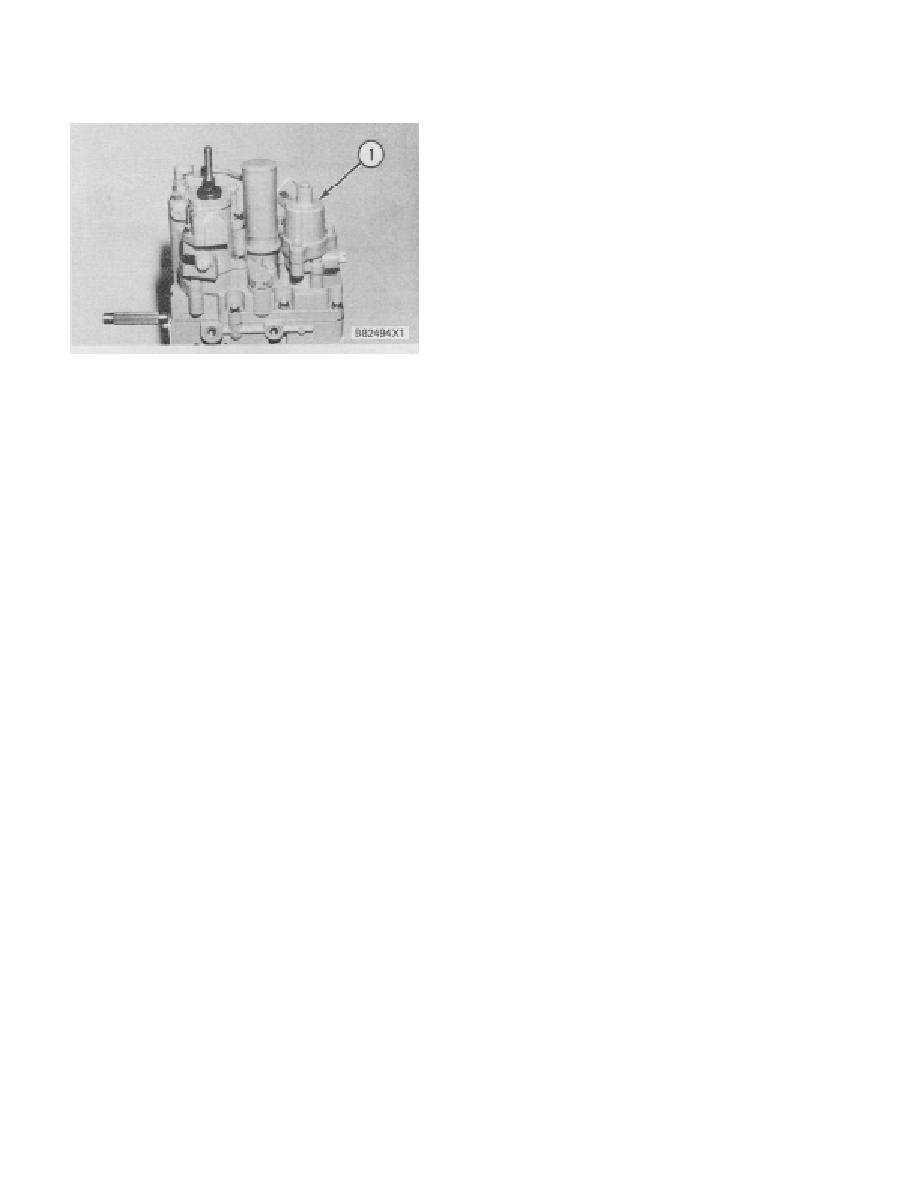

3161 GOVERNOR WITH AN AIR FUEL

up until the port is closed again. At this time the limiter

RATIO CONTROL

piston is stopped in a new position that is proportional to

1. Air fuel ratio control.

the air pressure in the inlet manifold.

The air fuel ratio control assembly (1) is installed

Now, with the engine in operation at a steady

on the right rear corner of the top cover. The control is

speed, load added decreases engine speed.

The

factory calibrated and installed. This control is not for

governor moves to increase fuel as the power piston

field installation.

moves up to turn the output shafts in the "increase"

direction. As the output shafts turn, the right end of the

The air fuel ratio control is similar to hydraulic air

limit floating lever is lifted. Because the limit floating

fuel ratio controls used on current Caterpillar engines.

lever is fastened to a pivot (pivot position is set by the air

This control automatically controls the governor output

fuel ratio control), the left end of the lever pushes the

shaft movement in the "fuel increase" direction, until air

limit/shutdown rod down. The limit/shutdown pilot valve

pressure in the engine inlet manifold is high enough to

plunger closes off governor control oil to the power

give complete fuel combustion.

piston and limits the power piston movement.

The air fuel ratio control limits the fuel to the

As the engine picks up load, air pressure to the

engine in proportion to the amount of turbocharger boost

air fuel ratio control increases. The rolling diaphragm

pressure (pressure above atmospheric) in the inlet

assembly moves up and lifts the fuel limiter plunger

manifold. The control is not activated during engine start

which opens the port in the limiter piston. Oil pressure

up and is cocked (activated) by a combination of oil

on the limiter piston is lowered, and lets the limit servo

pressure and the initial surge of boost when the engine is

spring push the piston and output rod up. This lets the

first loaded.

limit/shutdown pilot valve move up. Fuel limit level is

then increased.

Engine Start Up

NOTE: The air fuel ratio control fuel limit range is set by

As the engine is started and the speed or load is

the position of the limit cam on the limit lever. When the

increased, air pressure from the inlet manifold increases

cam is moved away from the shutdown rod, the limit

and pushes up on the rolling diaphragm assembly to put

range is longer. When the cam is moved closer to the

the limiter spring under compression. As the rolling

shutdown rod, the limit range is shorter.

diaphragm assembly moves up, the fuel limiter plunger

also moves up and closes off the port in the limiter

piston. Now the supply oil can not drain through the

167

|

||

|

||