| Tweet |

Custom Search

|

|

|

||

3161 GOVERNOR

TESTING AND ADJUSTING

AUXILIARY CONTROLS

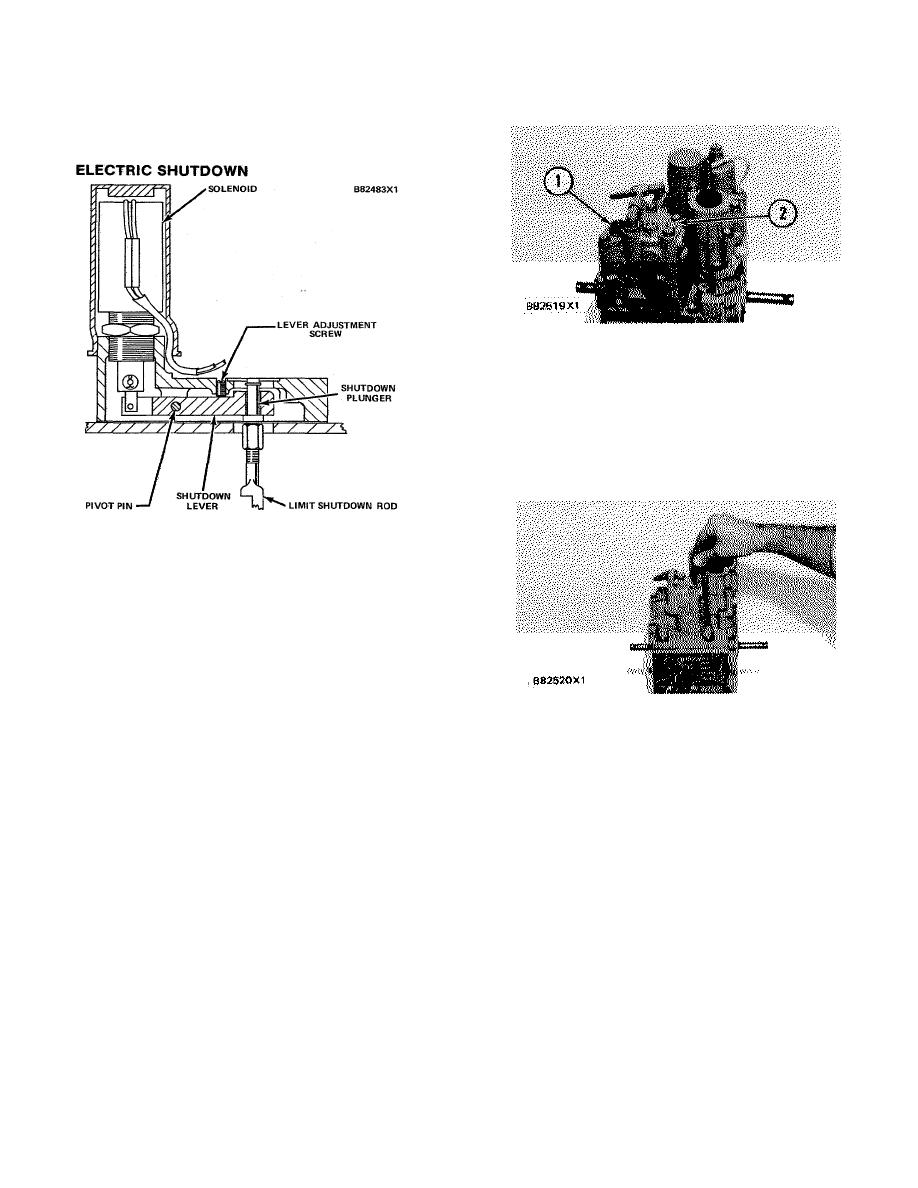

ELECTRIC SHUTDOWN

PNEUMATIC SPEED SETTING CONTROL 1. Bellows.

2. Plug over low idle adjustment screw.

The other is the pneumatic speed level ratio

(bias spring) adjustment, made by removing plug (2) and

turning the adjustment screw with a 1/8 inch hex wrench.

Pneumatic Speed Level Ratio Adjustment

The shutdown lever in the electric shutdown

assembly is adjusted up or down to keep the shutdown/

limit rod in the correct position until the shutoff solenoid

is activated.

1.

Install the gasket and electric shutdown on top of

the governor. Tighten the bolts to 10 Nom (90 lb. in.).

2.

Remove the cover, manual shutdown or

pressure shutdown, if so equipped, from the top of the

electric shutdown assembly.

ADJUSTMENT OF LOW IDLE

3.

Turn the adjustment screw until the shutdown

When the speed level adjusting screw is turned

plunger is even with the top of the gasket for the cover or

the low speed setting of the pneumatic control is

other shutdowns.

changed.

4.

Install the cover, manual shutdown or pressure

With the plug removed, put a 1/8 in. hex wrench

shutdown, if so equipped.

in the hole until it engages with the adjustment screw.

Turn the screw clockwise to decrease the low idle

PNEUMATIC

SPEED

SETTING

CONTROL

setting. Turn the screw counterclockwise to increase the

ADJUSTMENTS

low speed setting.

The pneumatic speed setting control has two

Feedback Spring

adjustments.

One is the speed range bellows

adjustment made by turning the bellows (1) inside the

To use the pneumatic speed setting control with

bellows housing to increase or decrease the speed

different air pressure ranges and engine speed settings

range.

the feedback spring must be changed.

192

|

||

|

||