| Tweet |

Custom Search

|

|

|

||

HYDRAMECHANICAL PROTECTIVE SYSTEM

SYSTEMS OPERATION

HYDRAMECHANICAL PROTECTIVE SYSTEM

The hydramechanical protective system is de-

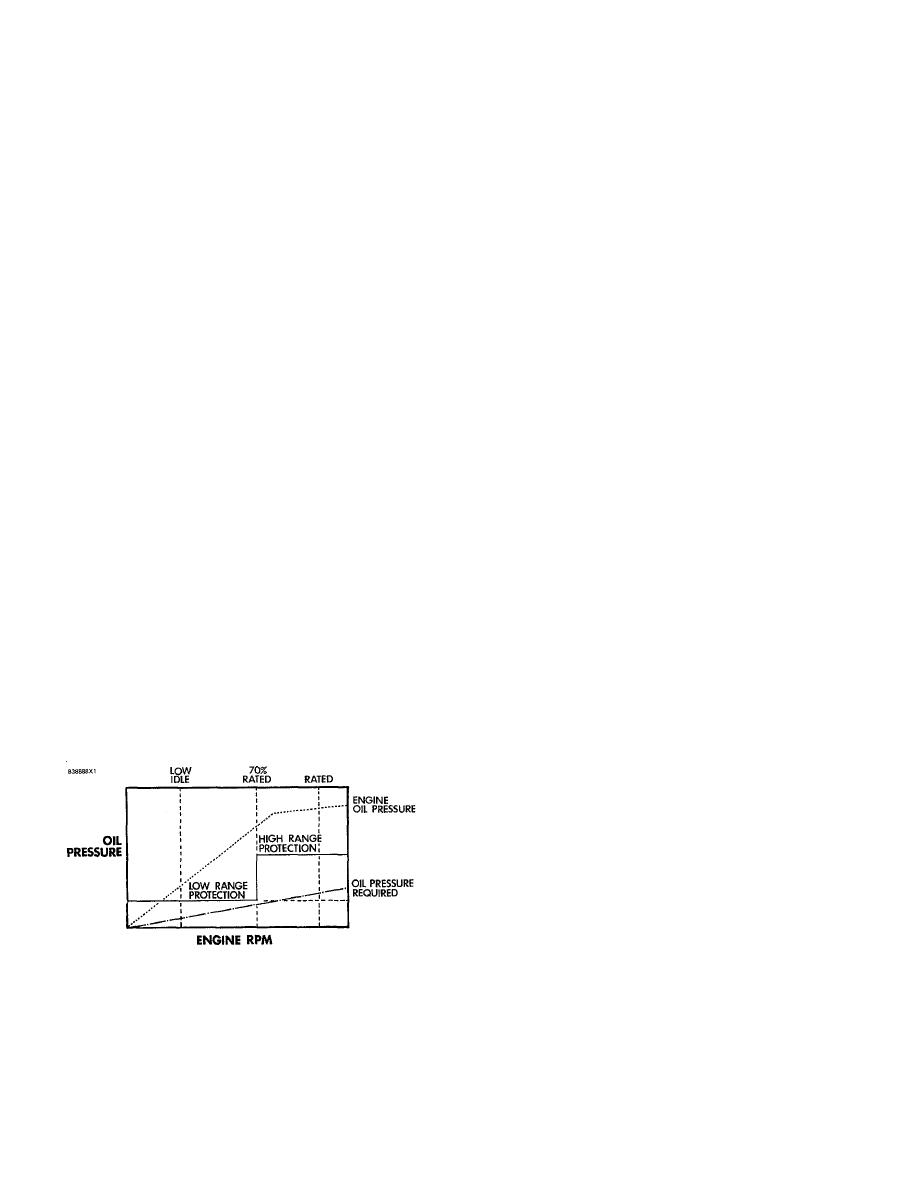

From Figure 1, it can be seen that if only the low

signed as a self contained system separate from the

range oil pressure protection level was used for the full

engine governor. This system is used to activate an

speed range, the engine could operate at rated speed

alarm or shutdown an engine for low oil-pressure, high

with oil pressure below the required level. Also, if only

coolant temperature or engine overspeed conditions.

the high range oil pressure protection level was used for

the full speed range, the system would shutdown the

engine at low idle, since the engine oil pump develops

OVERSPEED

lower pressure at that speed. Therefore, the protective

system must operate between the required oil pressure

In general, an overspeed condition is the result

curve and the engine oil pressure curve. This is done

of a fuel system that fails to operate correctly. This in

with a step action of pressure versus speed.

turn allows the combustion system to get more fuel than

the engine load needs. The excess fuel can accelerate

The

hydramechanical

protective

system

the engine to a point that engine failure can be the result.

operates within the two ranges of engine oil pressure.

As engine speed increases, the minimum oil pressure

The rate of engine acceleration is controlled by

needed at the main bearings also increases. At low

several factors. Friction horsepower, attached inertial

engine speed, an alarm or fuel shutoff actuator will

loads and operating loads make up the main affects on

activate when oil pressure is reduced to within 140 35

acceleration. In most all cases, the protective system

kPa (20 5 psi). At high engine speeds, an alarm or fuel

must have a response time of less than one second.

Response time is the time interval between the

shutoff actuator will activate when oil pressure is reduced

overspeed and the actuation of the protective system.

to within 205 35 kPa (30 5 psi).

The protective system must provide this response under

different conditions such as engine start up at extreme

For a low oil pressure condition, the protective

ambient temperatures and under full load operation.

system activates an alarm or moves the fuel control

linkage, through the governor, to the "SHUTOFF"

For an overspeed condition the fuel control linkage is

position. The combustion air supply is not shutoff for this

moved to the "SHUTOFF" position and the engine

condition.

combustion air supply is stopped.

HIGH COOLANT TEMPERATURE

LOW ENGINE OIL PRESSURE

If the coolant temperature of an engine goes

As engine speed increases, the required oil pressure for

above a set limit, the protective system activates an

main bearing protection increases. The engine oil pump

alarm or moves the fuel control linkage to the

is a positive displacement type pump, therefore, engine

"SHUTOFF" position to shutdown the engine. The

oil pressure varies in direct proportion to speed until the

combustion air supply is not stopped under this

pump goes on controlled bypass.

condition.

SYSTEM COMPONENTS

The system consists of an emergency manual

shut- off, a shutoff control group, a diverter valve, a

thermostatic pilot valve, an air inlet shutoff and a fuel

shutoff actuator for the governor.

The air and fuel shutoff systems are separate

from each other to give complete engine shutdown for an

overspeed condition. If the engine fuel is held in the

"ON" position, the air inlet shutoff must work to shutdown

the engine.

FIGURE 1. TWO-STEP OIL

PRESSURE PROTECTION

211

|

||

|

||