| Tweet |

Custom Search

|

|

|

||

HYDRAMECHANICAL PROTECTIVE SYSTEM

SYSTEMS OPERATION

SYSTEM HYDRAULICS

Engine lubrication oil (under pressure) is sent to

the oil reservoir for the shutoff control. The reservoir

keeps the correct level of oil for the system and drains

the excess oil back into the engine. This gives a

constant oil supply to the system.

An oil pump and pressure relief valve (located in

the shutoff control group) supplies oil flow and pressure

for the protective system hydraulic circuits.

There are two main hydraulic circuits in the protective

COOLANT TEMPERATURE PROTECTION

system. One circuit is for the fuel shutoff and the other is

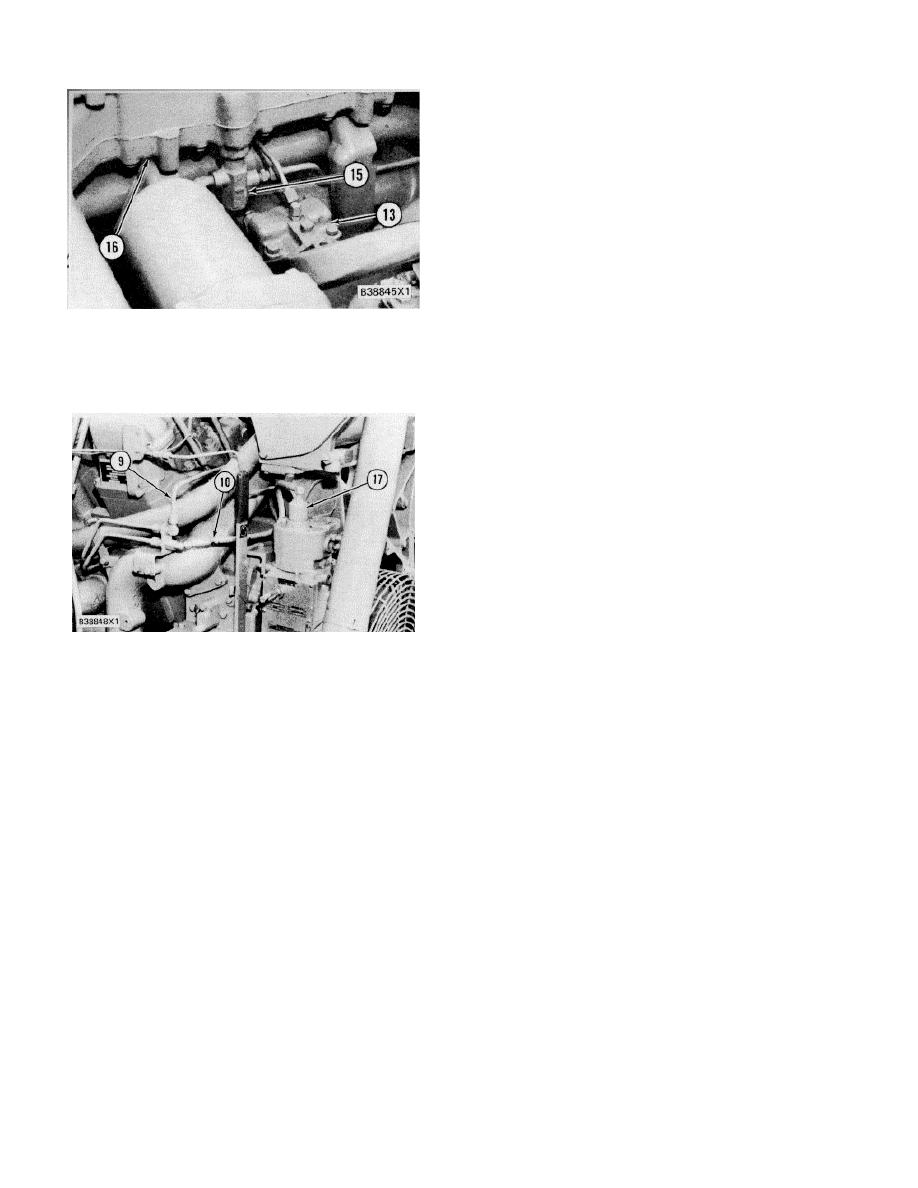

13. Aftercooler housing (coolant inlet). 15.

for air inlet shutoff. A constant flow of oil through the air

Thermostatic pilot valve. 16. Housing (below

inlet shutoff circuit removes (bleeds) air and keeps the

regulator housing).

lines full of oil to give a minimum time for system

response. If a fault condition occurs, the oil pressure in

one or both hydraulic circuits is increased to operate an

actuator to shutdown an engine or activate an alarm.

HYDRAULIC CIRCUITS (EARLIER)

(Without Check Valves In Diverter Valve)

The schematics that follow, show only hydraulic

actuators that are filled to cause engine shutdown. The

fuel shutoff actuator can be replaced with an electric

solenoid that is operated by the system hydraulics with

the use of a pressure switch.

NOTE: Some of the schematics show only the

GOVERNOR SHUTOFF ACTUATOR

components needed for explanation and do not show the

(Woodward UG-8 Governor Shown)

complete hydramechanical protective system circuits.

9. Oil line to thermostatic pilot valve. 10. Oil line to

fuel shutoff actuator. 17. Fuel shutoff actuator.

214

|

||

|

||