| Tweet |

Custom Search

|

|

|

||

3500 ENGINES

DISASSEMBLY AND ASSEMBLY

CYLINDER HEADS

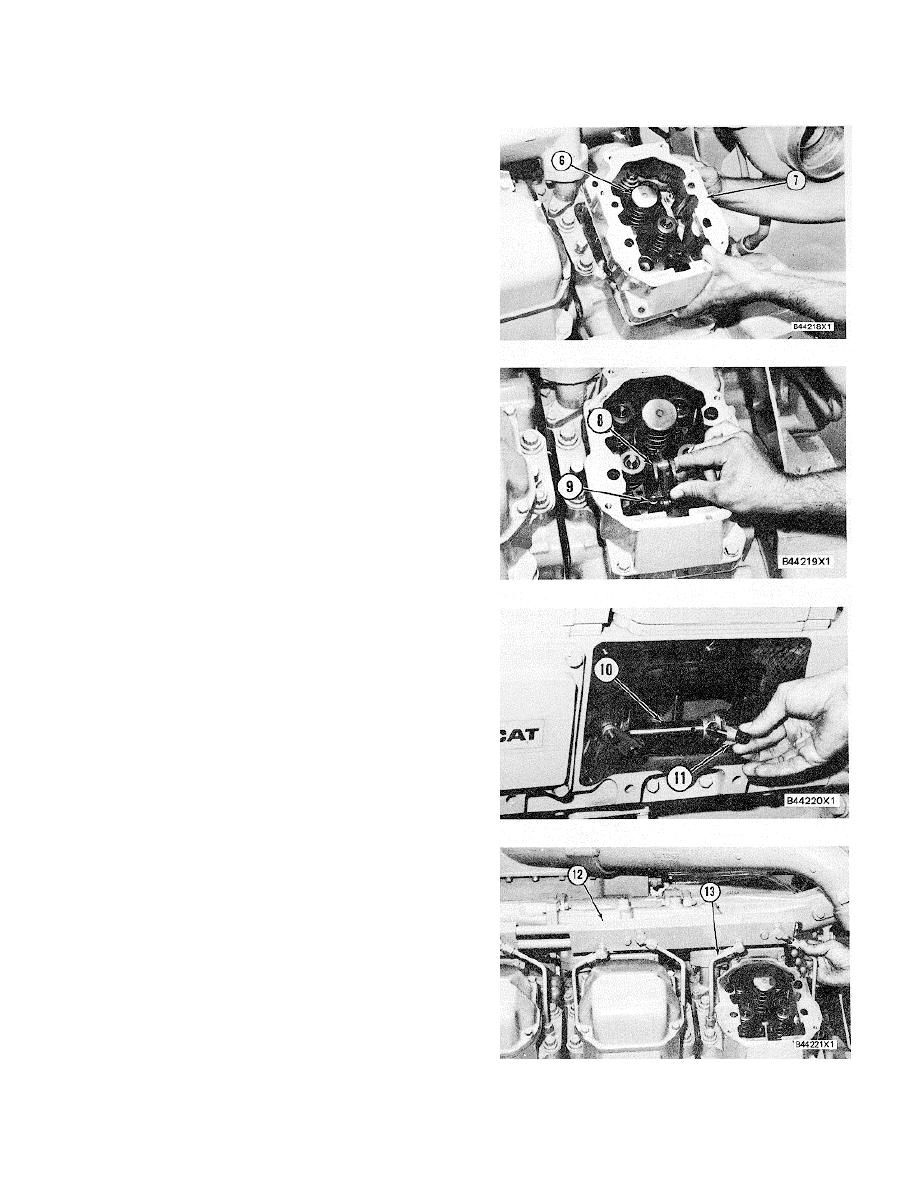

9.

Make sure the three O-ring seals are installed on

injector (6) and put clean engine oil on them and

in the bore for the injector.

NOTICE

Do not tap or hit on the injector follower to install the

injector. Damage and failure to the injector can be

the result.

10.

Put injector (6) in position. Install the clamp,

washer and bolt. Tighten the bolt to push

injector (6) all the way in its bore. Tighten the

bolt to a torque of 65 + 7 Nm (48 + 5 lb. ft.).

11.

Check to make sure the fuel injection rack

moves freely by hand in the injector after the

injector is installed.

12.

Make sure the O-ring seals are installed around

the three dowels in the bottom of valve cover

base (7). Put the gasket and base (7) in position

and install the bolts to hold them to the cylinder

head.

13.

Put fuel control rod assembly (9) and lever

assembly (8) in position in the cylinder head. If

necessary, use tool (B) to turn the engine fly

44219Xl

wheel until the camshaft moves

enough to permit the lever of rod assembly (9) to

move into position.

14.

Make sure lever assembly (8) is engaged

correctly with the fuel injection rack and install

the two bolts and washers to hold it in place.

15.

See TESTING AND ADJUSTING section for

the correct adjustment of the fuel injection

control group.

16.

Make sure the lever for the fuel control and

assembly is in position on control shaft (10) and

install the bolt and cap (11).

17.

Install the access cover and seal over the

camshaft and control shaft (10).

18.

Make sure the 0-ring seals for the fuel manifold

and lines are installed and have clean engine oil

on the seals. Install fuel manifold (12) and fuel

lines (13) on the engine.

19.

Turn the fuel supply to the engine.

20.

Fill the cooling system with coolant to the correct

level.

end by:

a) install rocker shafts and push rods

380

|

||

|

||