| Tweet |

Custom Search

|

|

|

||

3500 ENGINES

DISASSEMBLY AND ASSEMBLY

CYLINDER LINERS

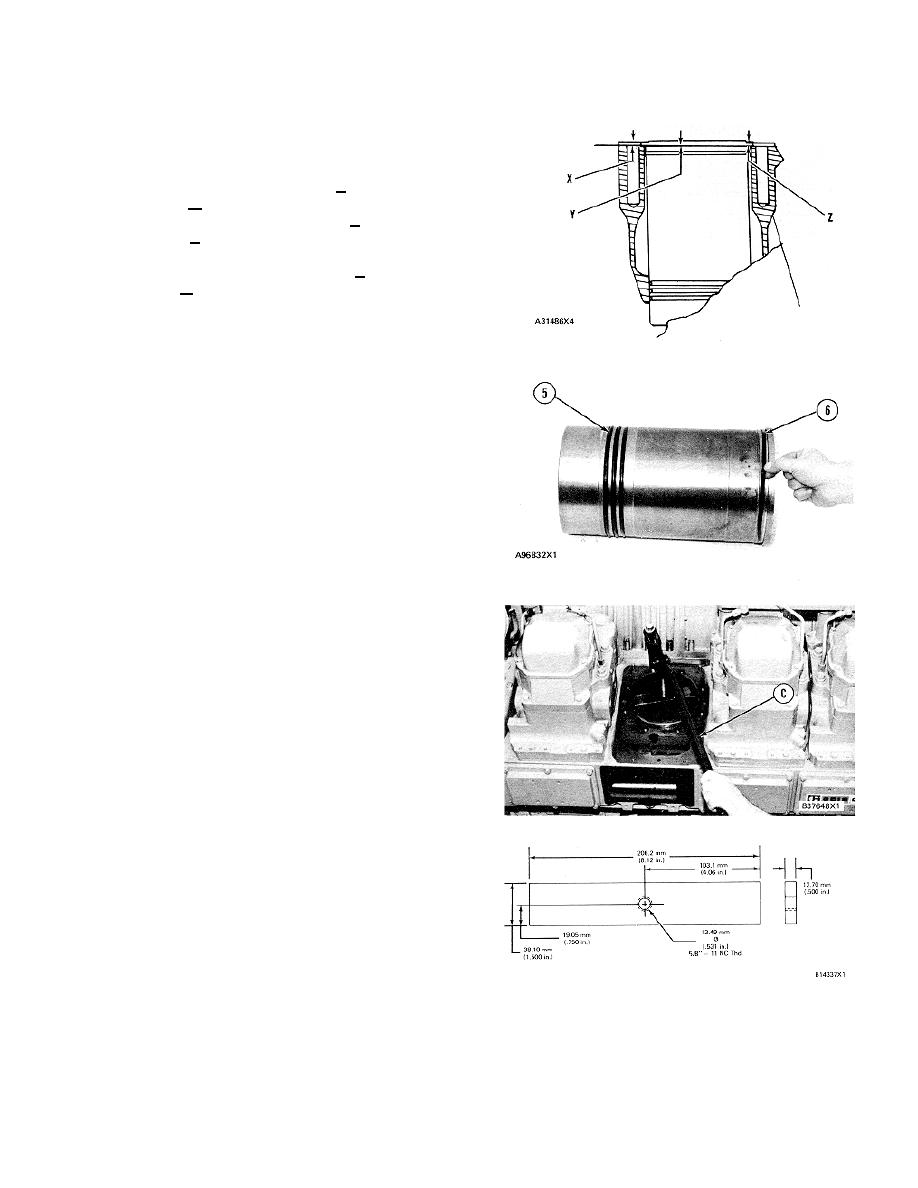

5. If the liner projection is not 0.059 to 0.199 mm (.0023

to .0078 in.), check the thickness of the following

parts:

a) Spacer plate (X): 10.313 + 0.025 mm

(.4060 + .0010 in.).

b) Spacer plate gasket (Y): 0.208 + 0.025 mm

(.0082 + .0010 in.). [All surfaces must be

clean and dry when gaskets are installed].

c) Cylinder liner flange (Z): 10.65 + 0.02 mm

(.419 + .001 in.).

6.

Put a mark on the cylinder liners and block so

the liners can be installed in same position.

7.

Remove tooling (A) and tool (B). Remove the

liner.

8.

Put liquid soap on seals (5), grooves of the liner

and the bore of the block. Install the seals on the

cylinder liner.

9.

Put the filler band completely in clean engine oil

for a moment. Install filler band (6) in the groove under

the liner flange without delay.

10.

Install the liner immediately after the filler band is

installed before expansion of the band. Make sure the

mark on liner is in alignment with the mark on the block.

Use tooling (C) to push the liner into position.

11.

Use Steps 7 through 10 for the remainder of the

liners.

end by:

a) install pistons

399

|

||

|

||