| Tweet |

Custom Search

|

|

|

||

3500 ENGINES

DISASSEMBLY AND ASSEMBLY

CAMSHAFT BEARINGS, CRANKSHAFT

b)

Follow Steps 2, 3 and 4 to install the

tooling and pull the bearing into the

center of its bore.

c) Check the bore in bearing (1) after it is

installed. The bore must be 86.00 +

0.06 mm (3.386 + .002 in.).

end by:

a) install camshafts

REMOVE CRANKSHAFT

1202-11

start by:

a) remove rocker shafts and push rods

b) remove front drive housing

c) remove front balancer group (3508)

d) remove rear gear group (Step 1 only)

e) remove piston cooling jets

NOTICE

The rocker shafts and push rods do not have to be

removed to remove the crankshaft but bent push

rods can be the result if they are not removed.

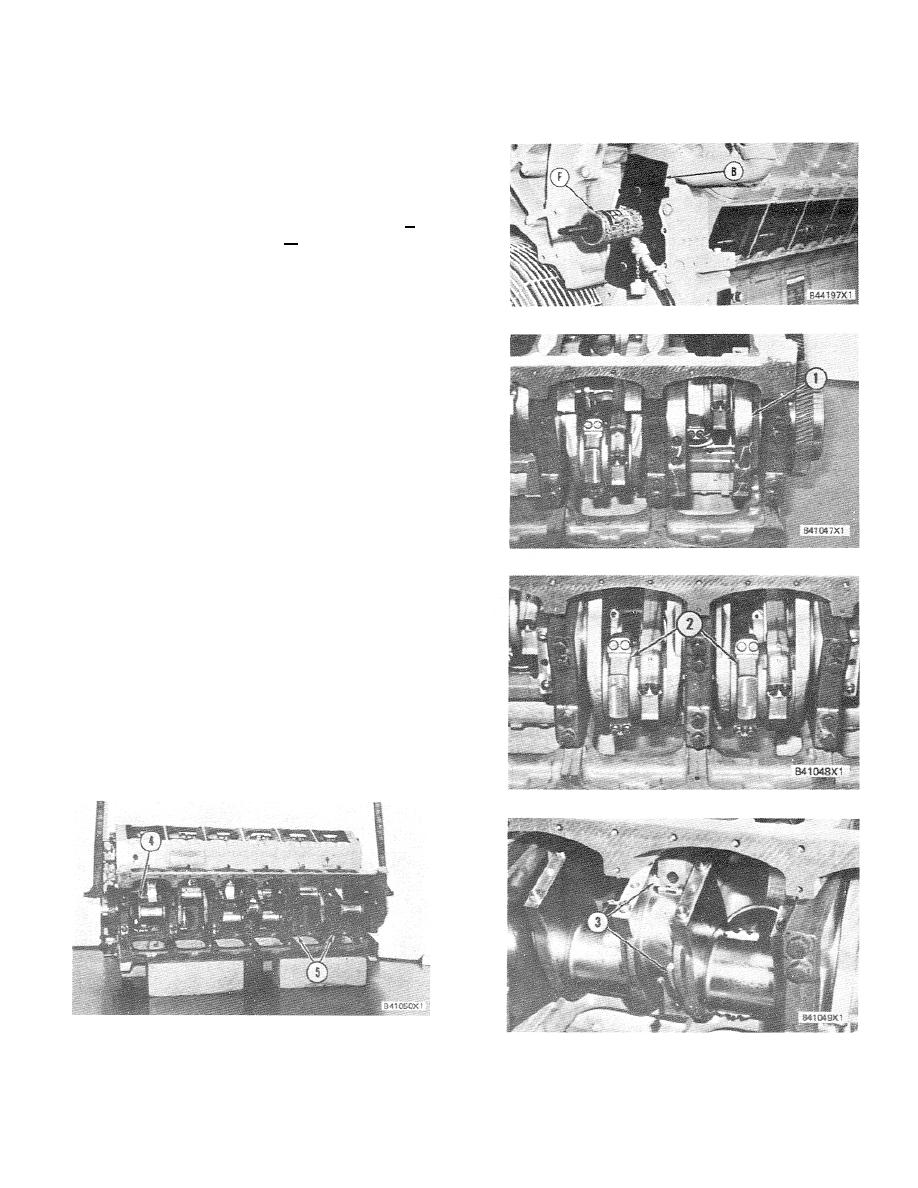

1. Put the engine in the position as shown.

The weight of the 3512 Engine is

approximately 5443 kg (12, 000 lb.). The

weight of the 3508 Engine is approximately

4445 kg (9800 lb.).

2. Remove counterweights (1) from the

crankshaft.

3. Remove bearing caps (2) from the

connecting rod and push the connecting

rods away from the crankshaft. Use wire to

hold the upper half of the connecting rods

away from the crankshaft.

4. Remove the center main bearing cap and

remove two thrust plates (3) from each side

of the main bearing.

5. Use two of the bolts that hold the flywheel

to the crankshaft and install a bolt in each

end of the crankshaft. Fasten a hoist to the

crankshaft as shown.

407

|

||

|

||