| Tweet |

Custom Search

|

|

|

||

ELECTRIC PROTECTIVE SYSTEM

TROUBLESHOOTING

C

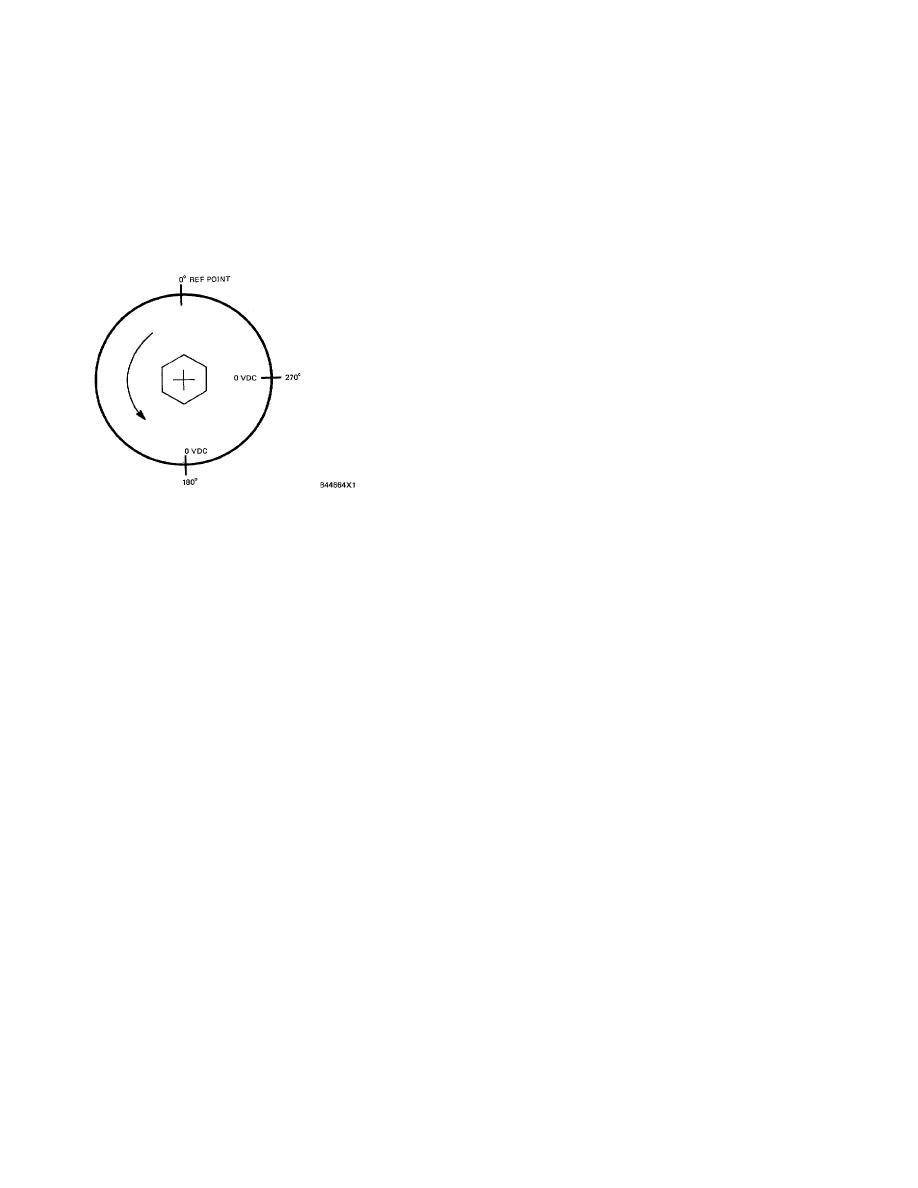

With the negative (-) voltmeter lead still

connected to ESS-5, connect the positive ( + )

voltmeter lead to SW3 (ESS-3). Again, slowly

turn the sensor shaft counterclockwise. A 4 to 6

VDC reading should be seen for all but two small

areas of shaft rotation; one at the 1800 interval

and one at the 2700 interval (both measured

from the SWI 0 reference point). Zero volts will

be indicated at both of these areas.

SW3 CHECK

2.

If all four zero volt levels are recorded in the

proper sequence and at the proper degree of

rotational position (900 apart from each other),

then the 7N7412 Sensor Assembly operates

properly.

3.

Before installing 7N7412 Sensor Assembly (2)

back on the engine, start the engine and check

to be sure that the drive shaft in tachometer

drive housing (1) is turning properly.

4.

If tachometer drive shaft is in rotation, stop

engine and install sensor assembly.

NOTE: The tachometer drive housing has two output

drives (one marked A and the other marked B).

Be sure that sensor assembly is always

connected to output drive marked A.

502

|

||

|

||