| Tweet |

Custom Search

|

|

|

||

ELECTRIC PROTECTIVE SYSTEM

TROUBLESHOOTING

PROCEDURE E

3.

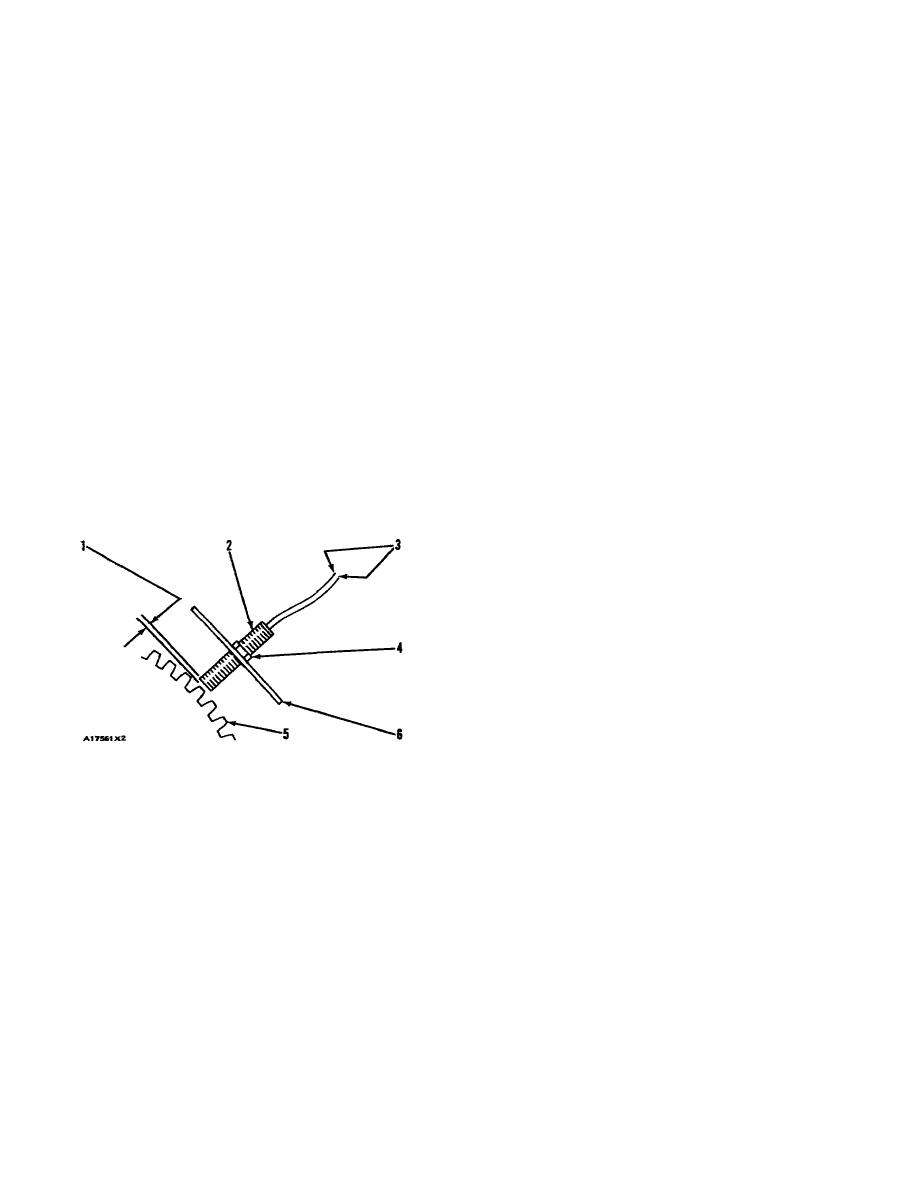

Remove magnetic pickup (2) from the engine

MAGNETIC PICKUP VERIFY

flywheel housing (earlier location, front drive

housing) and turn the flywheel until a gear tooth

1.

Connect a 6V7070 Multimeter (or a voltmeter of

(5) is directly in the center of the threaded

same accuracy) to electronic speed switch

opening for the magnetic pickup. Install the

common terminal (ESS-3) and signal terminal

magnetic pickup again in the threads of housing

(ESS4). Set the meter voltage scale to a scale

(6).

greater than 1.5 VAC. Start the engine and run

at idle rpm or 600 rpm (whichever is greater).

By hand, turn in a clockwise direction until the end

of the magnetic pickup just makes contact with the gear

If the measured voltage is 1.5 VAC or more, the

tooth (5). Now turn the magnetic pickup back out 1/2

operation of the magnetic pickup is correct. If measured

turn (180 in the counterclockwise direction) to get the

voltage is less than 1.5 VAC, go to Step 2.

correct air gap [clearance dimension (1)]. Now tighten

locknut (4) to a torque of 68 13 Nm (50 + 10 lb. ft.).

2.

Disconnect the wiring from the magnetic pick- up

and connect the voltmeter to magnetic pick- up

NOTE: Do not let the magnetic pickup turn while

connector terminals I and 2. Set the volt- meter

locknut is tightened.

voltage scale to a scale greater than 1.5 VAC.

Start the engine and run at idle rpm or 600 rpm

Do Step 2 again. If voltage is still less than 1.5

(whichever is greater).

VAC, replace the magnetic pickup.

If the measured voltage is 1.5 VAC or more,

repair or replace the wiring between the magnetic pickup

and the electronic speed switch. If the measured voltage

is less than 1.5 VAC, go to Step 3.

MAGNETIC PICKUP

1. Clearance dimension. 2. Magnetic pickup. 3.

Wires. 4. Locknut. 5. Gear tooth. 6. Housing.

552

|

||

|

||