| Tweet |

Custom Search

|

|

|

||

Every 10 Service Hours or Daily

Walk-Around Inspection

Inspect Engine

1.

Make sure lines are properly clamped and tight.

Check for loose fittings or leaks.

2.

All guards must be in place. Repair or replace

missing or damaged guards.

3.

Disconnect any battery chargers that are not

protected against the starter current drain. Check

condition of batteries and the level of electrolyte.

4.

Check for coolant, fuel or oil leaks on or below

engine.

For changing engine oil filter elements see topic entitled

"Engine Crankcase." NOTE

5.

Check condition of all belts.

Replace if

: Follow the Lubrication and Maintenance Chart under

necessary.

normal operation.

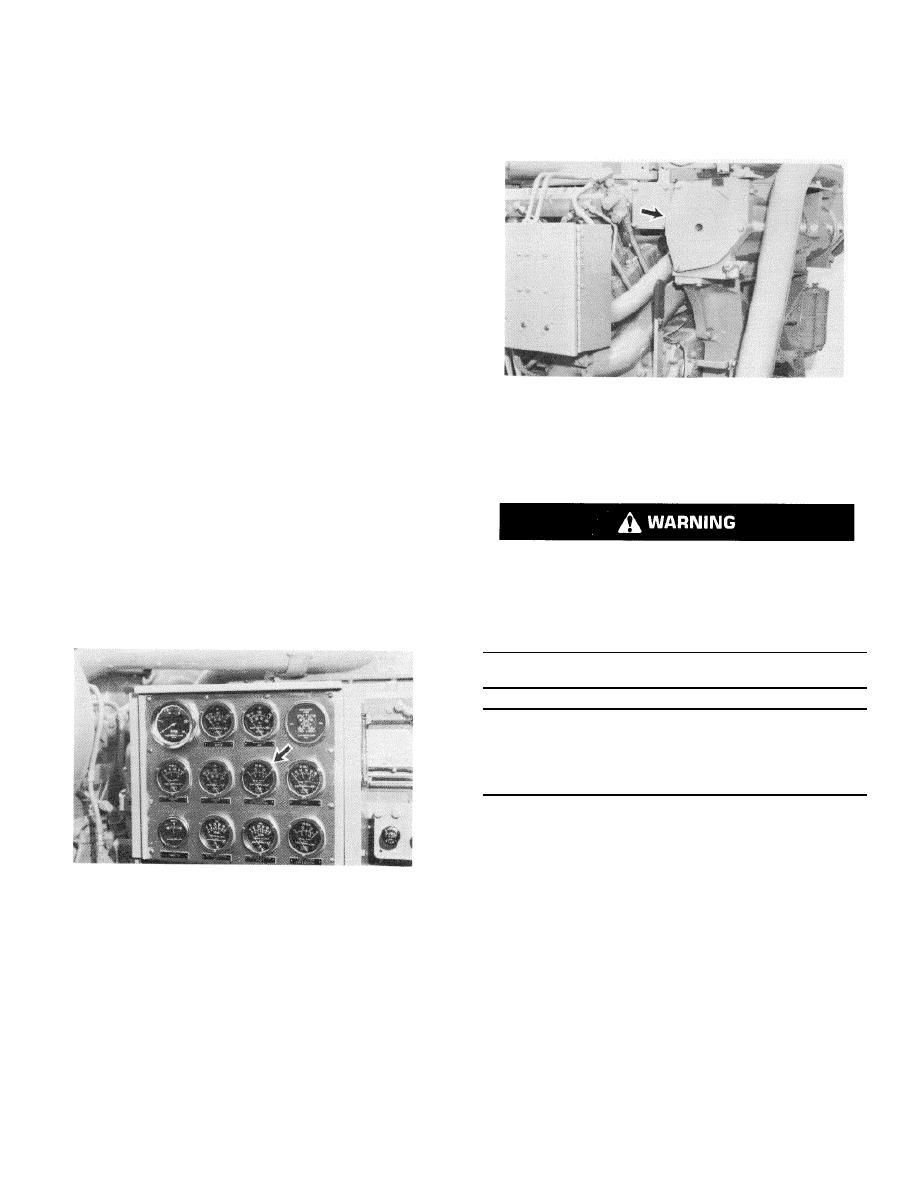

6. Check condition of gauges. Replace if cracked or

Fuel System

not calibrated to "O."

7.

While operating, frequently observe the engine

oil pressure gauge, the fuel pressure gauge, the fuel filter

differential pressure gauges, the oil filter differential

pressure gauges, and the air cleaner differential

Fuel leaked or spilled onto hot surfaces or electrical

pressure gauges.

components can cause a fire.

Engine Oil Filter

Disconnect the battery when changing fuel filters.

NOTICE

Do not fill fuel filter housings with fuel before installing

elements. Contaminated fuel will cause accelerated

wear to fuel system components.

The engine oil filter elements should be changed when

the oil filter differential pressure gauge registers 105 kPa

(15 psi) when engine is at rated speed, and is at

operating temperature.

597

|

||

|

||