TM 5-2815-241-34&P

FUEL PUMP CALIBRATION - CONTINUED

ACTION

LOCATION

ITEM

REMARKS

IDLE SPEED TESTING AND ADJUSTING

NOTE

If pressure is low and the adjusting screw bottoms, stop the test stand, add shims to the

spring end of the adjusting screw (see Fuel Pump, page 2-289) and retest cutoff rpm

and throttle leakage, steps 27 and 28.

Each time governor barrel assembly cover or spring pack adjusting tool is removed, run

pump until purged of air.

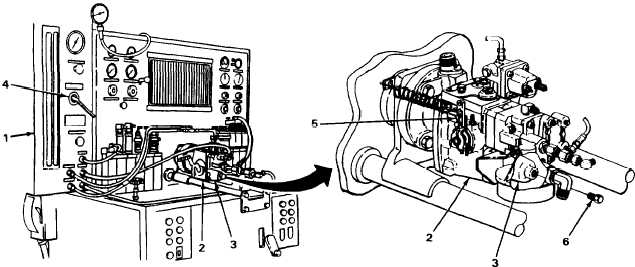

29. Test stand (1)

Fuel pump (2)

Test and adjust idle speed as follows:

governor barrel

assembly cover (3)

a.

b.

C.

Place selector valve (4) in IDLE

position.

d.

e.

f.

g.

Increase fuel pump speed to 500 rpm.

Pull throttle lever (5) to idle position.

Fuel pressure gage should read 28 psi

(179.27 kPa).

If fuel pressure is not 28 psi (179.27

kPa), adjust idle screw using ST-984

barrel assembly adjusting tool.

After proper adjustment is made, stop

test stand (1) and remove ST-984 barrel

assembly adjusting tool.

Install barrel assembly cover plug (8).

Purge fuel pump of air (see step 24).

T A 2 4 2 5 6 6

2-344

|

|