TM 5-3895-360-13

6-3. ENGINE CRANKSHAFT, PISTON, AND CONNECTING ROD REPLACEMENT (Con’t).

h.

i.

j.

k.

l.

m.

n.

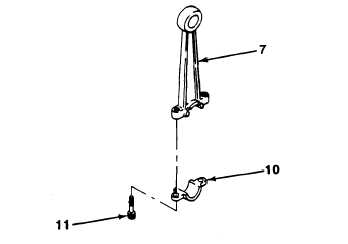

Inspect connecting rod for cracks, breaks, and dam-

aged threads. Restore damaged threads using die

and tap threading set.

NOTE

Refer to Figure 6-14, Measuring Connecting

o.

Rod Bores, for steps i through n.

Using inside caliper micrometer, measure piston pin

bore diameter of connecting rod (7). Measurement

must be 0.6870-0.6875 in. (17,4498-17.4625 mm).

Replace connecting rod if measurement is not within

specification.

Place connecting-rod (7) in vise with caps,

install connecting rod cap (10) on connecting rod (7)

with two screws (11 ).

Using inside caliper micrometer, measure bore di-

ameter of connecting rod (7) and connecting rod cap

(10). Diameter must be 0.9399-0.9403 in.

(23.8735-23.8836 mm).

Remove two screws (11) and connecting rod cap

(10) from connecting rod (7).

Remove connecting rod (7) from vise.

NOTE

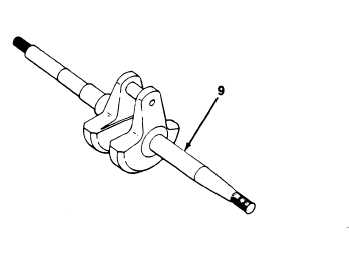

Refer to Figure 6-15, Measuring Crankshaft,

for step o.

Using outside caliper micrometer, measure connect-

ing rod surface of crankshaft (9). Measurement must

be 0.7493-0.7496 in, (19.0322-19.0398 mm). Re-

place crankshaft if measurement is not within speci-

fication.

Figure 6-15. Measuring Crankshaft.

p. Using inside caliper micrometer, measure cylinder

bore diameter at three points:

(1) Measure ¼ in. (6.35 mm) down from top of cylin-

der.

(2) Measure ¼ in. (6.35 cm) up from exhaust port.

(3) Measure 3/16 in. (4.76 mm) down from lower

edge of intake port

Figure 6-14. Measuring Connecting Rod Boxes.

6-12

|

|