4-24.

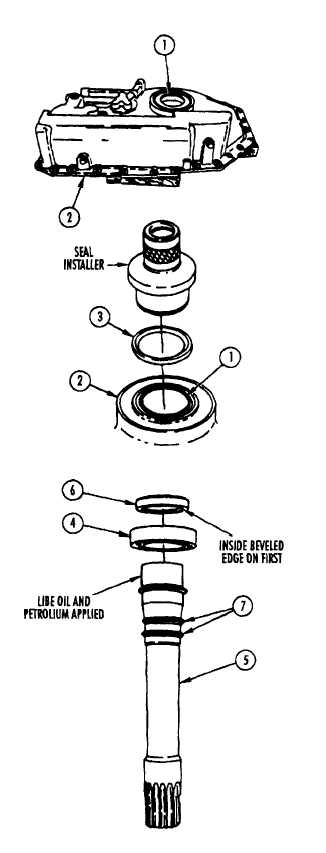

ASSEMBLE LEFT END COVER ASSEMBLY

(SHEET 3 OF 5)

CAUTION

Do not reuse output shaft seal after it has been removed.

Removal of seal destroys dry sealant on outer edge of

seal.

NOTE

Seal installed numbered side out.

2

Using seal installer and ball peen hammer,

install seal

(3) in bore (1). Seat seal flush to 0.010 inch (0.254

mm) below surface of end cover (2).

WARNING

Frozen parts can stick to your fingers and cause serious

injury. Always wear leather gloves when working with

parts that have been frozen in dry ice.

3

Place shaft (4), bearing end in dry ice for 1 hour.

Install Bearing and Sleeve on LH Output Shaft

4

If output shaft bearing (4) was removed, apply

petrolatum and lubricating oil to bearing end of

LH output shaft (5).

5

Using arbor press, install new bearing (4),

numbered end out, on output shaft (5). Press

bearing to shoulder.

WARNING

Hot parts can burn you. Always wear

leather gloves when working with parts

that are or might be hot.

6

If sleeve (6) was removed, heat sleeve for 30

minutes to approximately 250°F (121°C) using

heat gun.

7

Using arbor press, install sleeve (6) on output

shaft (5) with inside beveled edge on first. Press

sleeve to bearing (4).

8

Install two seal rings (7) on output shaft (5).

Coat two seal rings (7) with petrolatum.

9

Position left end cover, inside upward. Block

cover so that it is level.

10

Apply petrolatum to inner surface of seal (3).

Go to Sheet 4

Para. 4-24, Task 2

Change 2 4-157

|

|