|

|

|

|

|

TM9-2815-202-34

NOTE

Insert counterbore has a diameter of 1.2600 to 1.2610 inches and a depth of 0.3380 to

0.3520 inch. Counterbores must be concentric with valve guides within 0.003 inch total

indicator reading.

(d) Immerse cylinder head in water heated to 180o-200oF (82°-93oC) for 30 minutes or cool

insert with liquid nitrogen.

NOTE

Install insert in cylinder head while head is still hot and insert is at room temperature or

when insert is chilled and head is at room temperature.

(e)

(9

(9)

Place cylinder head on a bench with bottom side up. Place insert in counterbore with

valve seat side facing up.

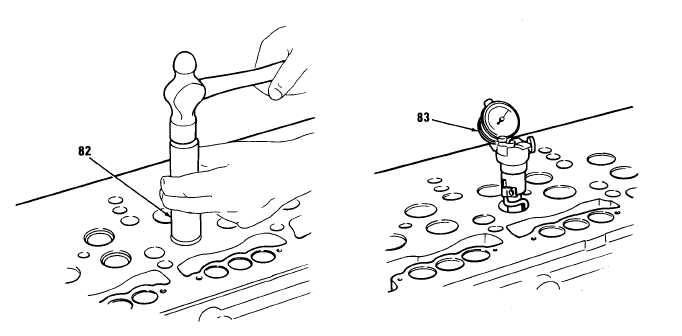

Using insert installer (82), drive insert in place until it seats solidly in cylinder head.

Check exhaust valve seat inserts for concentricity in relation to valve guides using insert

runout gage (83).

NOTE

Exhaust valve seat inserts are prefinished. Only check for concentricity after

installation. Grind insert only if runout exceeds 0.002 inch.

4-195

|

|

|

|

|

Privacy Statement -

Copyright Information. -

Contact Us