TM9-2815-202-34

5-37. CYLINDER HEAD REPAIR (Cont)

b. Cleaning

(1) Thoroughly clean cylinder head and cylinder head components (refer to Para 3-2).

(2) Clean galleries in cylinder head using probes and brushes.

(3) If water passages are heavily coated with scale, remove injector tubes and water nozzles and

thoroughly clean water jacket areas.

c. Pressure Check Cylinder Head

(1)

NOTE

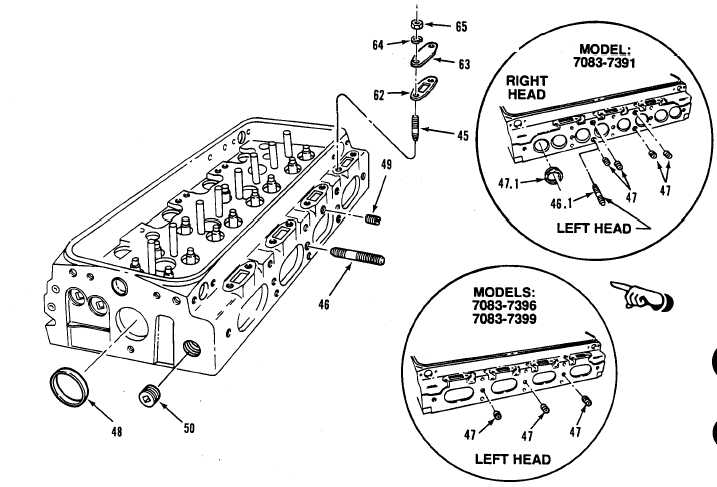

Before pressure checking cylinder head, cup plug (48), water manifold studs (45), two

pipe plugs (50), fuse plug (49), exhaust manifold studs (46), four exhaust manifold studs

(46.1) (left head only model 7083-7391, and three pipe plugs (47) (left head only

models 7083-7396 and 7083-7399) or our pipe plugs (47) (right head only model

7083-7391 ) must be in position.

For models 7083-7396 and 7083-7399, position four gaskets (62) and four cover plates (63)

over studs (45) and secure with eight Iockwashers (64) and eight nuts (65). Torque nuts to

20-25 lb-ft (27-34 N-m).

For model 7083-7391, position three gaskets (62) and three cover plates (63) over studs (45)

and secure with six washers (64) and six nuts (65). Torque nuts to 20-25 Ib-ft (27-34 N-m).

Install scrap or dummy injectors to properly

seal injector tubes. Torque injector clamp

bolts to 20-25 Ib-ft (27-34 N-m).

(1.1)

(2)

5-42

C h a n g e 1

|

|