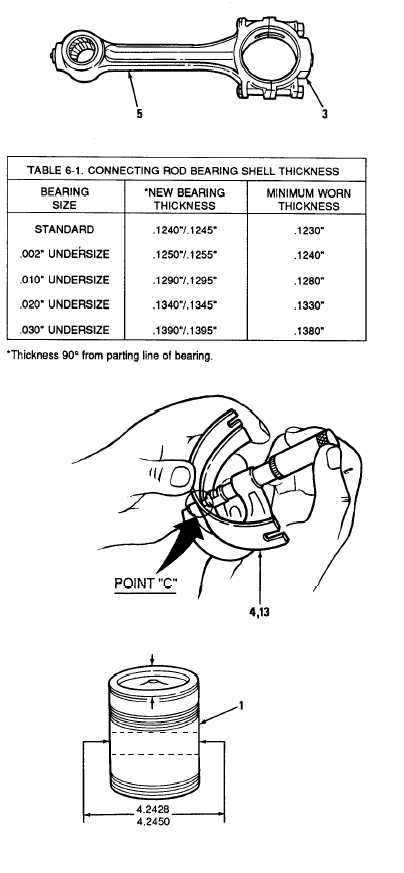

TABLE 6-1.

TM9-2815-202-34

(9) When installing a new connecting

rod assembly, stamp cylinder

number on connecting rod (5)

and cap (3).

(4) Connecting Rod Bearings

(a)

(b)

If one

Inspect bearing shells for scoring,

pitting, flaking, etching, and dirt

grooving. If defective, discard

bearing shells.

Discard bearing shells with bright

spots on backs indicating

movement in bearing caps or

supports.

NOTE

bearing shell is less than

minimum thickness shown in Table

6-1, replace both bearing shells

(upper-and lower).

(c) Using a micrometer and ball

attachment, measure thickness of

lower bearing shell (4) and upper

bearing shell (13) at point “C”, 90

degrees from parting line.

e. Fitting Piston

NOTE

Fit new or used piston to

corresponding cylinder liner and

retain as matched set for assembly

in engine.

(1) Using a micrometer, measure piston

skirt outside diameter parallel to and

perpendicular with piston pin bore at

room temperature, 70oF (21 oC).

Diameter must be 4.2428 to 4.2450

inches. Taper and out of round must

not exceed 0.0005 inch.

6-35

|

|