TM9-2815-202-34

6-38. TURBOCHARGER REPAIR (Cont)

(11)

(12)

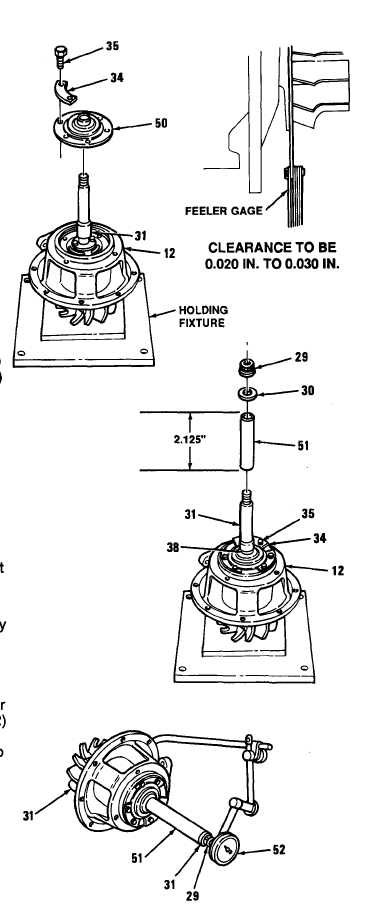

Slide thrust plate assembly (50) over

rotor assembly (31 ). Aline holes in

thrust plate assembly with holes in

center housing assembly (12).

Install three locking plates (34) and

(13)

(14)

(15)

(16)

(17)

(18)

six bolts (35) securing thrust plate

assembly (50) to center housing

assembly (12). Torque bolts to

80-100 lb-in (9-11.4 N-m).

NOTE

Back plate shim comes in a 0.010

inch thickness.

Push rotor assembly (31) toward

compressor end of turbocharger.

Using feeler gage, measure

clearance between rotor assembly

and back plate (43). Repeat steps (2)

thru (12) to add or remove shims (44)

until clearance is between 0.020 to

0.030 inch.

Bend up tangs on locking plates (34)

against heads of bolts (35).

Install fabricated sleeve (51) over

shaft of rotor assembly (31) and

against face of thrust collar (38).

Sleeve length is 2.125 inches.

Secure rotor assembly and center

housing assemblv (12) in place with

washer (30) and nut (29). Tighten nut

securely.

Using dial indicator (52), measure

axial play of rotor assembly (31). Play

should be 0.005 to 0.010 inch.

Remove nut (29), washer (30), and

sleeve (51).

Install diffuser shims (33) and diffuser

(27) on center housing assembly (12)

and secure with four nuts (25) and

four Iockwashers (26). Torque nuts to

150-200 lb-in (17-22 N-m).

6-50

|

|