| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

GENERATOR ABNORMAL OPERATION (300 AMPERE)

THIS WORK PACKAGE COVERS:

Troubleshooting Table and Diagnostic Tests

INITIAL SETUP:

Tools:

Personnel Required

General mechanic's tool kit (item 121, WP 0176)

Track Vehicle Repairer (2) 63H10

Equipment Conditions:

Engine installed in vehicle or ground hop.

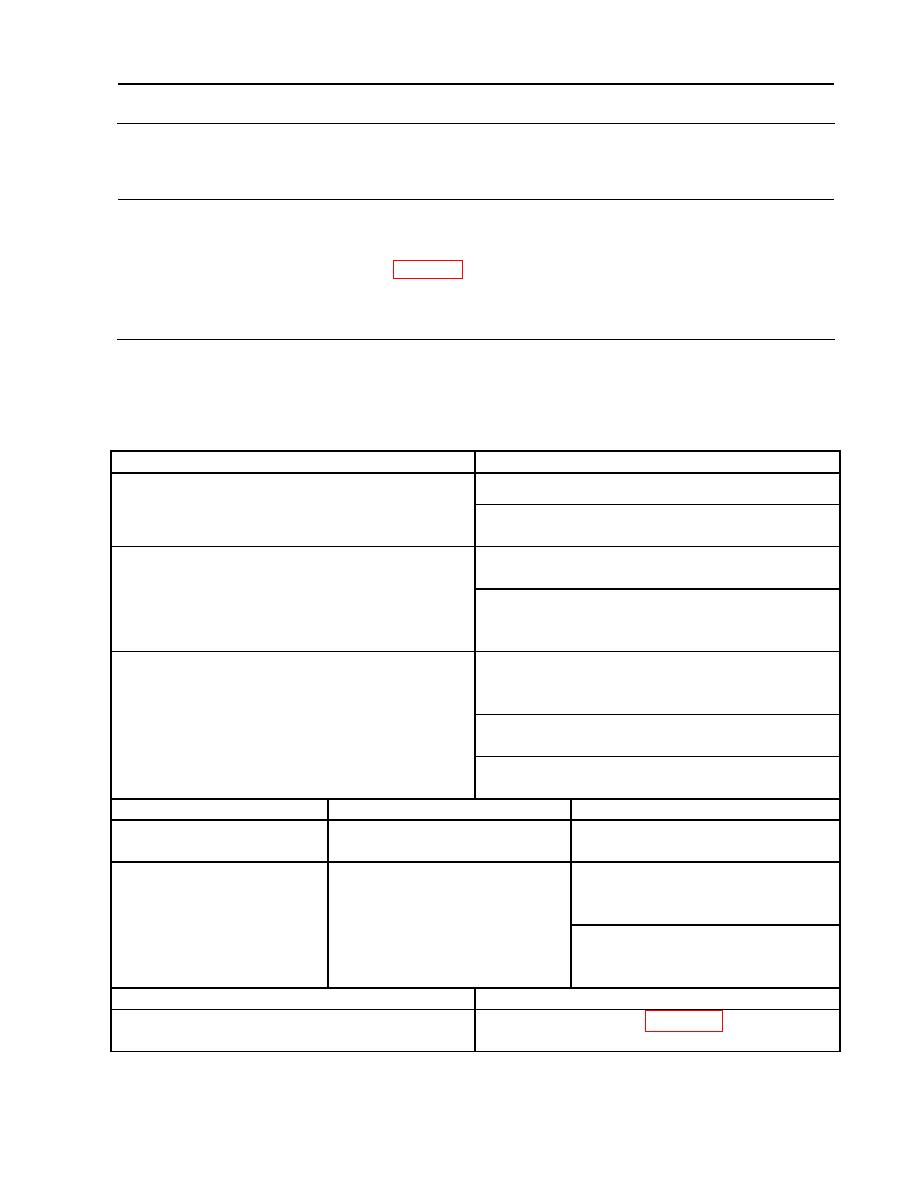

MALFUNCTION 1:

Not charging (indicator reads in "yellow" same as battery reading with engine stopped and

master switch "ON").

PROBABLE CAUSE

CORRECTIVE ACTION

a. Battery cables or terminals loose, corroded,

(1) Check battery condition.

broken or disconnected (connector nuts not

(2) Inspect and repair cables and terminals

tightened).

(refer to pertinent vehicle technical manual).

b. Defective electrical circuits or voltage

(1) Check circuits and voltage regulator (refer

regulator.

to pertinent vehicle technical manual).

(2) Repair and replace as necessary (refer to

pertinent vehicle or generator technical

manual).

c. Generator failed.

(1) Check circuits and generator (refer to

pertinent vehicle or generator technical

manual).

(2) Repair and replace as necessary (refer to

pertinent vehicle technical manual).

(3) Perform Generator Electrical Failure Test as

follows:

PROCEDURE

OBSERVATION

ANALYSIS

Remove generator from

engine.

Damaged winding burned

Inspect generator

Debris and odor indicates

insulation debris, and odor

windings and insulation

generator burned out. Rotational

also observe for debris in

(accessible through drive

bind indicates failure.

drain tubes and freeness of

end plate), and check for

If above not evidenced, generator

rotation, of generator shaft.

free rotation of drive shaft

may have electrical failure or

turning shaft by hand.

drive gear assembly failure.

PROBABLE CAUSE

CORRECTIVE ACTION

c. (Continued) Generator failed.

(4) Replace generator (WP 0052, Generator

Replacement 300 Ampere).

WP 0022 00-1

|

||

|

||