| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

FUEL INJECTION PUMP TIMING CHECK

THIS WORK PACKAGE COVERS:

Introduction, Removal, Timing Check, Timing Adjust, and Installation

INITIAL SETUP:

Tools:

Mandatory Replacement Parts:

Breaker bar, 3/4-inch (used with 2DR engine

Gasket (2) (item 329, WP 0175)

turning tool)

Personnel Required:

Engine (flywheel) turning tool for 2CA/2DA:

Track Vehicle Repairer (2) 63H10

splined wrench (item 136, WP 0176)

Equipment Conditions:

General mechanic's tool kit (item 121, WP 0176)

Engine removed from vehicle and placed on a

Fabricated Items:

flat stationary surface

Engine (flywheel) turning tool, 2DR only (item 4,

INTRODUCTION

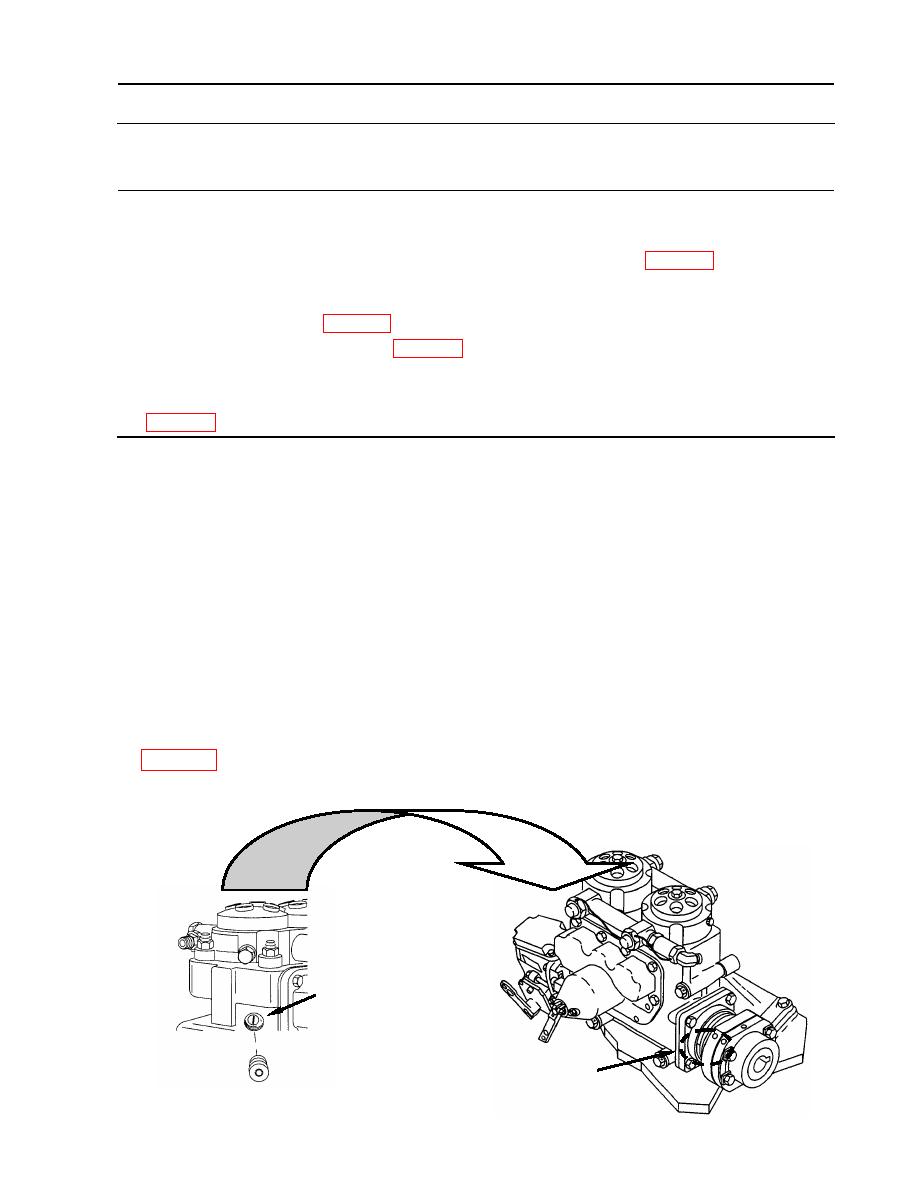

The engine crankshaft and camshafts must be properly oriented before checking the fuel

injection pump timing. It is possible for the external timing marks on the fuel injection pump

and on the engine flywheel to align and still have the fuel injection pump be 180 degrees out

of phase. The fuel injection pump has external timing marks (A) as well as an internal gear

tooth marking (B). The fuel injection pump drive coupling rotates two times to each

revolution of the internal gear tooth that is part of the timing process. In addition, the

crankshaft rotates two times to each revolution of the camshafts. Strict attention to the

procedure must be observed.

Flywheels between Models 2DA and 2DR are different and are not interchangeable. Timing

markings are identical. However, on Model 2DA, a timing pointer is affixed to the

transmission housing, while on Model 2DR there are scribed markings on the transmission

housing.

Methods for turning the crankshaft between models require different turning tools (see

For instructional purposes, a 2DR Model is described and illustrated. Timing is identical for

all 2-series engines.

B

A

WP 0036 00-1

|

||

|

||