| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

OIL SAMPLING VALVE REPLACEMENT (2DR)

0071 00

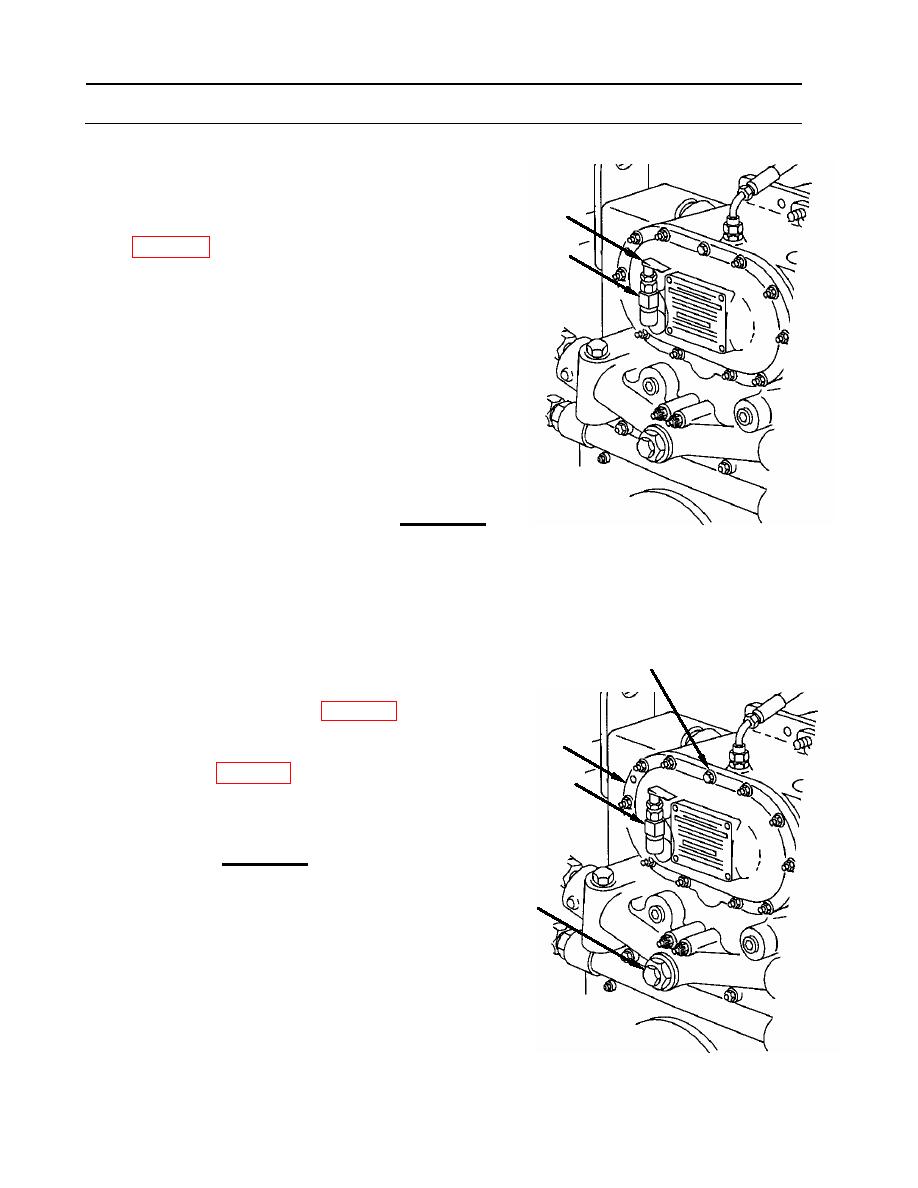

INSPECTION

All parts must be inspected with care.

Replace parts if damage or wear exceeds

9

allowable limits.

1. See WP 0028 for Standard Inspection

7

Procedures.

2. Assure that activation handle (9) of oil

sampling valve (7) is secure. If handle is

loose or damaged, replace valve.

3. Inspect oil sampling valve (7) for opening

and closing action. Valve must open and

close freely; if not, replace valve.

4. Check that valve does not leak. Replace any

valve that leaks.

INSTALLATION

CAUTION

Make sure oil sampling valve lever is parallel to oil filter cover and

that protective cap is installed and secured on sampling valve. Failure

to properly position oil sampling valve lever and secure protective cap

may result in loss of engine oil and equipment damage.

1. Install oil sampling valve (7) in cover (8).

2,3,4

2. Install vent cap screw (2).

a. Apply lubricant (item 21, WP 0173) to

threads of cap screw (2) and install with

8

flat washer (3) and new seal washer (4)

(item 158, WP 0175).

7

b. Torque-tighten vent cap screw (2) to

125-150 inch-pounds (14-17 Nm).

CAUTION

Failure to properly tighten drain

5

valve can result in damage to

engine. Valve must not be over

tightened, nor under tightened.

3. Apply lubricant to threads of drain plug (5)

and torque-tighten to 150 inch-pounds

(17 Nm).

END OF WORK PACKAGE

WP 0071 00-2

|

||

|

||