| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

PTO COUPLING/FUEL PUMP DRIVE HOUSING REPAIR (2DR ONLY)

0111 00

CLEANING

1. See Work Package 0028 for Standard Cleaning Procedures.

INSPECTION

All parts must be inspected with care. Replace parts if damage or wear exceeds allowable

limits.

1. See Work Package 0028 for Standard Inspection Procedures.

2. Take critical measurements. Replace any part that does not meet the limits specified in the

following table.

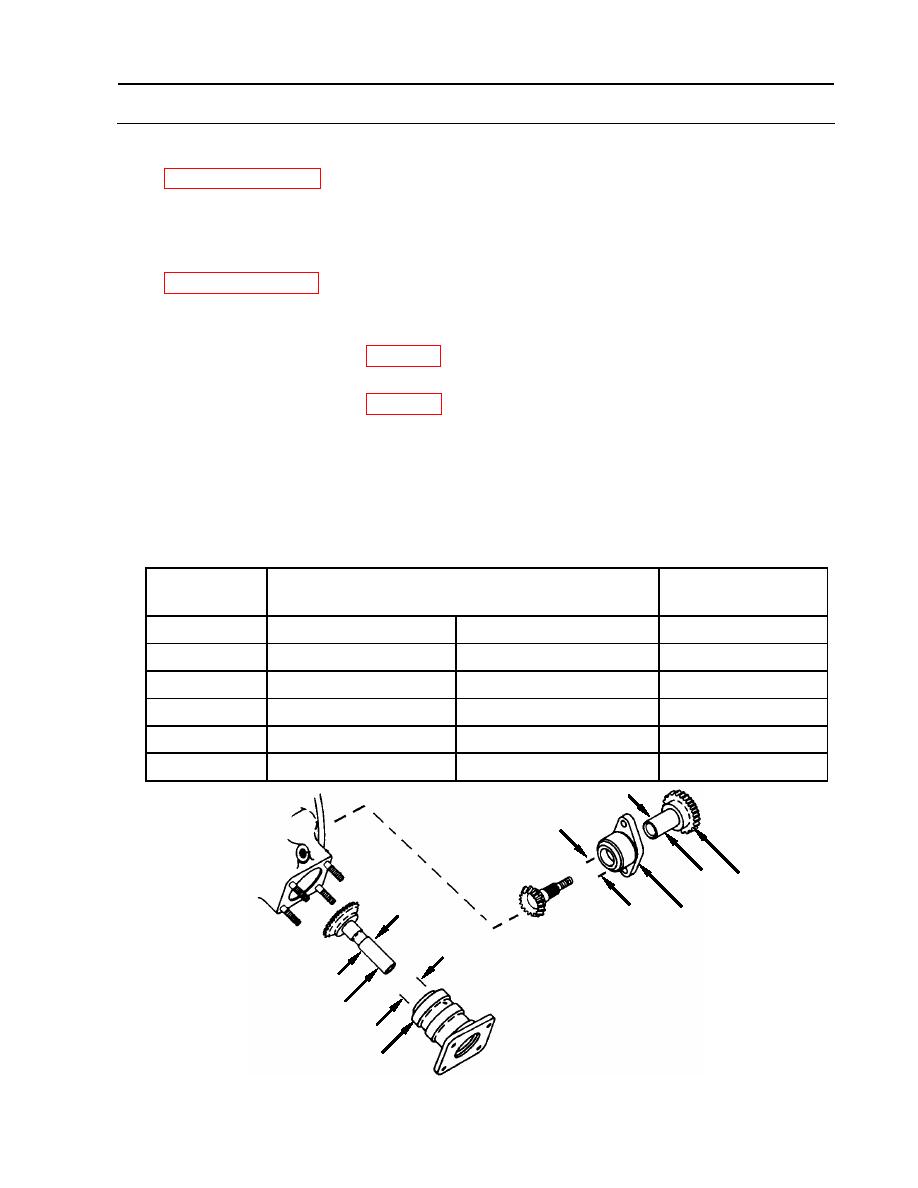

a. Using micrometer (item 17, WP 0176), measure outside shaft diameter (A) of spur

gear (21).

b. Using micrometer (item 16, WP 0176), measure inside diameter (B) of adapter (16) bore.

c. Calculate fit of spur gear shaft (21) in adapter (16) by subtracting measurement A from B.

See " Calculation a." in table below for limits.

d. Measure outside shaft diameter (C) of bevel gear shaft (15).

e. Measure inside diameter (D) of adapter (13) bore.

f. Calculate fit of gear shaft (15) in adapter (13) by subtracting measurement C from D. See

"Calculation b." in table below for limits.

Location

Sizes and Fits of New Parts

Wear Limits

inches (mm)

A

0.8090 (20.5486)

0.8100 (20.574)

0.8085 (20.5359)

B

0.8120 (20.6248)

0.8130 (20.6502)

0.8145 (20.6883)

Calculation a.

0.0020 (0.0508)

0.0040 (0.1016)

0.0050 (0.1270)

C

0.7465 (18.9611)

0.7475 (18.9865)

0.7460 (18.9484)

D

0.7495 (19.0373)

0.7505 (19.0627)

0.7510 (19.0754)

Calculation b.

0.0020 (0.0508)

0.0040 (0.1016)

0.0050 (0.1270)

B

A

21

16

C

15

D

13

WP 0111 00-5

|

||

|

||