| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

FUEL INJECTION TUBES REPLACEMENT

THIS WORK PACKAGE COVERS:

Disassembly, Cleaning, Inspection, Repair, and Assembly

INITIAL SETUP:

Tools:

Expendable and Durable Items:

Crowfoot attachment (item 27, WP 0176)

Goggles (item 27, WP 0173)

General mechanic's tool kit (item 121, WP 0176)

Lubricating oil (item 21, WP 0173)

Plug gauge set (item 53, WP 0176)

Lubriplate (item 23, WP 0173)

Torque wrench, 0-175 foot-pounds (item 127,

Cap, Plastic Tubing (Tool Crib)

Personnel Required:

Torque wrench, 0-300 inch-pounds (item 124,

Track Vehicle Repairer (1) 63H10

Equipment Conditions:

Fabricated Items:

Engine level on flat surface

Bending tool (2) (item 13, WP 0177)

Top housing assembly removed (WP 0055)

Mandatory Replacement Parts:

Fuel injection tube brackets removed (WP 0079)

Self-locking nut (31) (item 38, WP 0175)

Self-locking nut (item 111, WP 0175)

Self-locking screw (2) (item 223, WP 0175)

REMOVAL

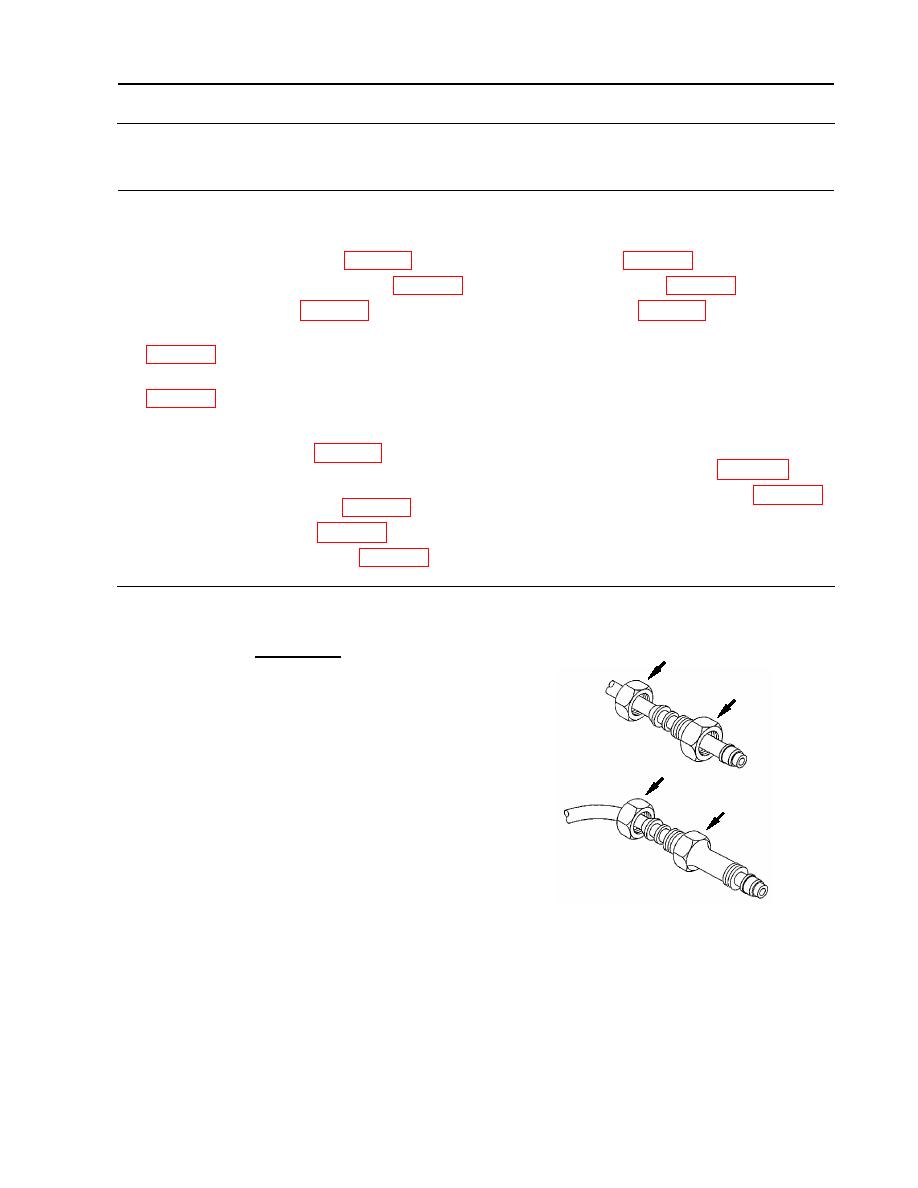

CAUTION

1

Both ends of each fuel injection

2

tube have a support nut (1) that

must be loosened prior to

loosening the compression nut (2)

[nozzle end] or compression

1

connector (3) [pump end]. The

compression nut or compression

3

connector must be held in place

while loosening the support nut.

Failure to comply may result in

damage to fuel injection tubes.

NOTE

Each fuel injection tube is unique and must be returned to its original

position. Each tube is marked for cylinder location.

WP 0113 00-1

|

||

|

||