| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

FUEL INJECTION TUBES REPLACEMENT

0113 00

INSTALLATION (Continued)

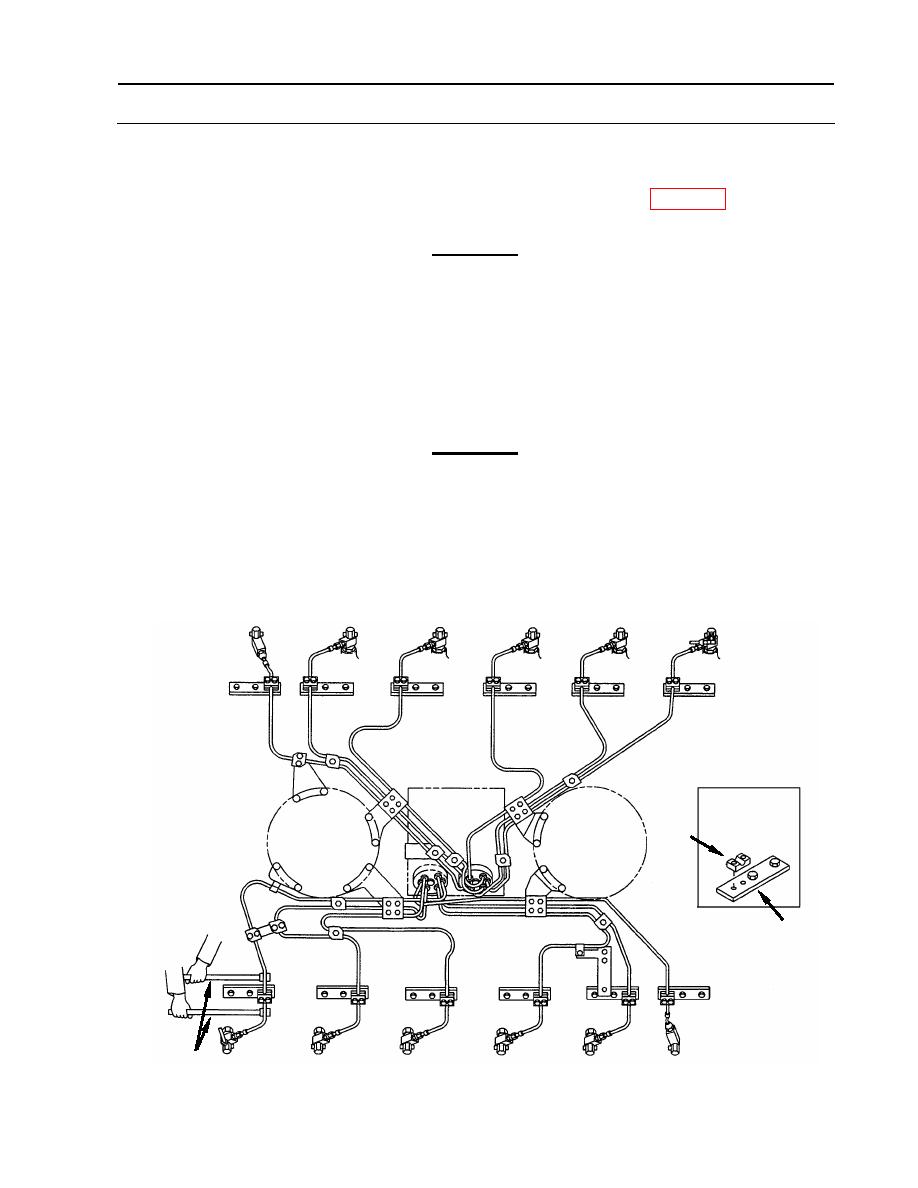

11. Check that all tube assemblies have 1/8 inch (3.175 mm) minimum clearance to each other at

pump end. Bend tubes as necessary, with bending tools (24) (item 13, WP 0177) to obtain

clearance.

CAUTION

When bending of tube assemblies is required at the pump end, the

compression connector and support nut must be re-torqued. Tighten

compression connector to 35 foot-pounds (48 Nm). Tighten support

nut to 125 inch-pounds (14 Nm).

12. Install 12 lower fairlead halves (28) between tube assemblies and brackets (33) at each

cylinder.

CAUTION

When bending injection tubes is required, be careful not to nick

tubing. The bending tools are designed to allow bending without

nicks.

13. Assure that fairlead halves (28) are aligned with bracket (33) holes and align tube to fit within

1/8 inch (3.175 mm) in any direction with fairlead half. Use two bending tools (24).

Right Bank

Damper End

Typical

(12 places)

28

33

Left Bank

24

WP 0113 00-9

|

||

|

||