| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

OIL PUMP REPAIR

0154 00

INSPECTION (Continued)

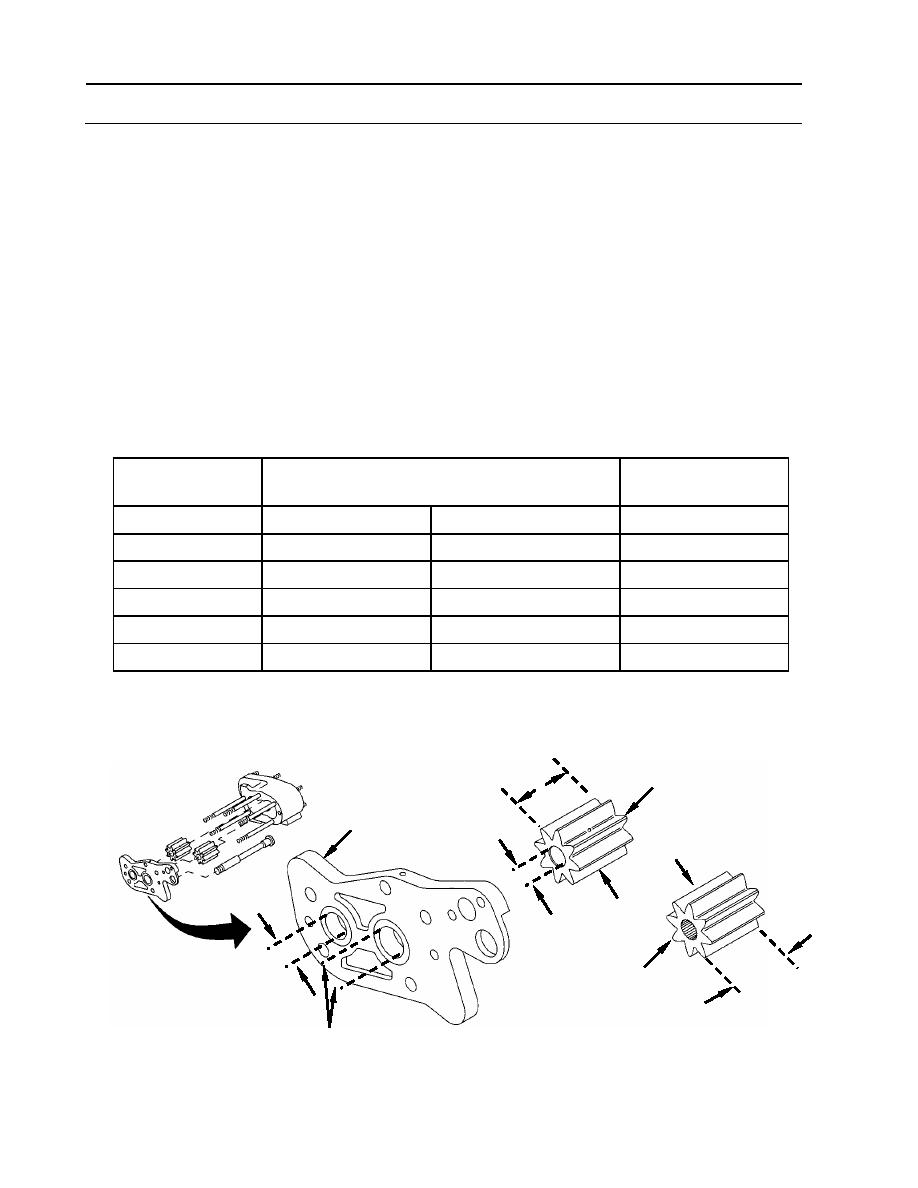

7. Measure inside diameters (A, B) of bushings in spacer assembly (42). Replace oil pump if not

within specifications in the following table.

8. Inspect scavenge compartment impellers (23 and 24).

a. Replace pump if any impeller has burrs, wear, cracked or broken teeth, or pitting at tooth

contact areas.

b. Measure length (C) of impellers (23 and 24). Replace oil pump if not within specifications

in the following table.

c. Measure inside (D) and outside (E) diameters of impeller (23). Replace oil pump if not

within specifications in the following table.

d. Measure outside diameter (F) of impeller (24). Replace oil pump if not within

specifications in the following table.

Location

Sizes and Fit of New Parts

Wear Limits

inches (mm)

A

1.1330 (28.7782)

1.1340 (28.8036)

1.1350 (28.829)

B

0.9843 (25.0012)

0.9848 (25.0139)

0.9853 (25.0266)

C

3.0410 (77.2414)

3.0420 (77.2668)

3.0405 (77.2287)

D

0.9860 (25.0444)

0.9865 (25.0571)

0.9870 (25.0698)

E

2.4774 (62.9259)

2.4778 (62.9361)

2.4770 (62.9158)

F

2.4794 (62.9767)

2.4798 (62.9869)

2.4790 (62.9666)

C

23

42

D

F

B

E

24

C

A

WP 0154 00-8

|

||

|

||