| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-1

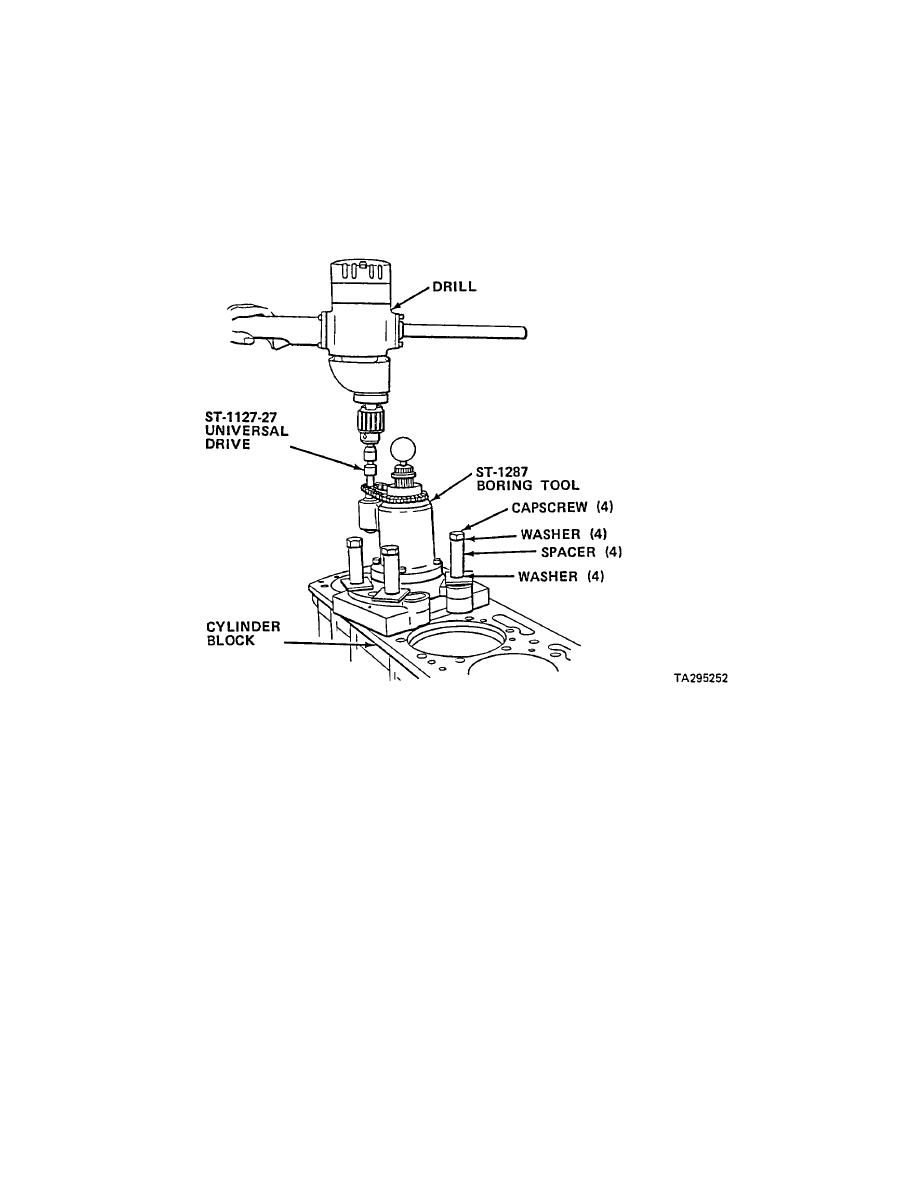

(4) Install counterbore salvage boring tool.

(a) Remove all nicks or bur rs from upper counterbore with emery cloth.

(b) Clean upper bore thoroughly to ensure smooth counterbore surface. This is necessary to provide

boring tool with proper alinement between upper and lower bores.

(c) Place boring tool on top of cylinder block over bore to be machined. Tapered centering ring will

engage with upper counterbore to center tool.

(d) Secure boring tool base plate to block with capscrews, washers, and spacers.

(e) Torque capscrews to 50 ft lbs. (68 N m).

(f) Slowly push downward on round knob until tool bit touches lower bore area.

(g) With round knob, raise drive shaft approximately 1.0 in. (25.4 mm).

(h) Turn round knob clockwise to tighten. This engages automatic feed (, mechanism.

(i) Rotate shaft by hand to ensure free rotation.

3-88

|

||

|

||