| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-1

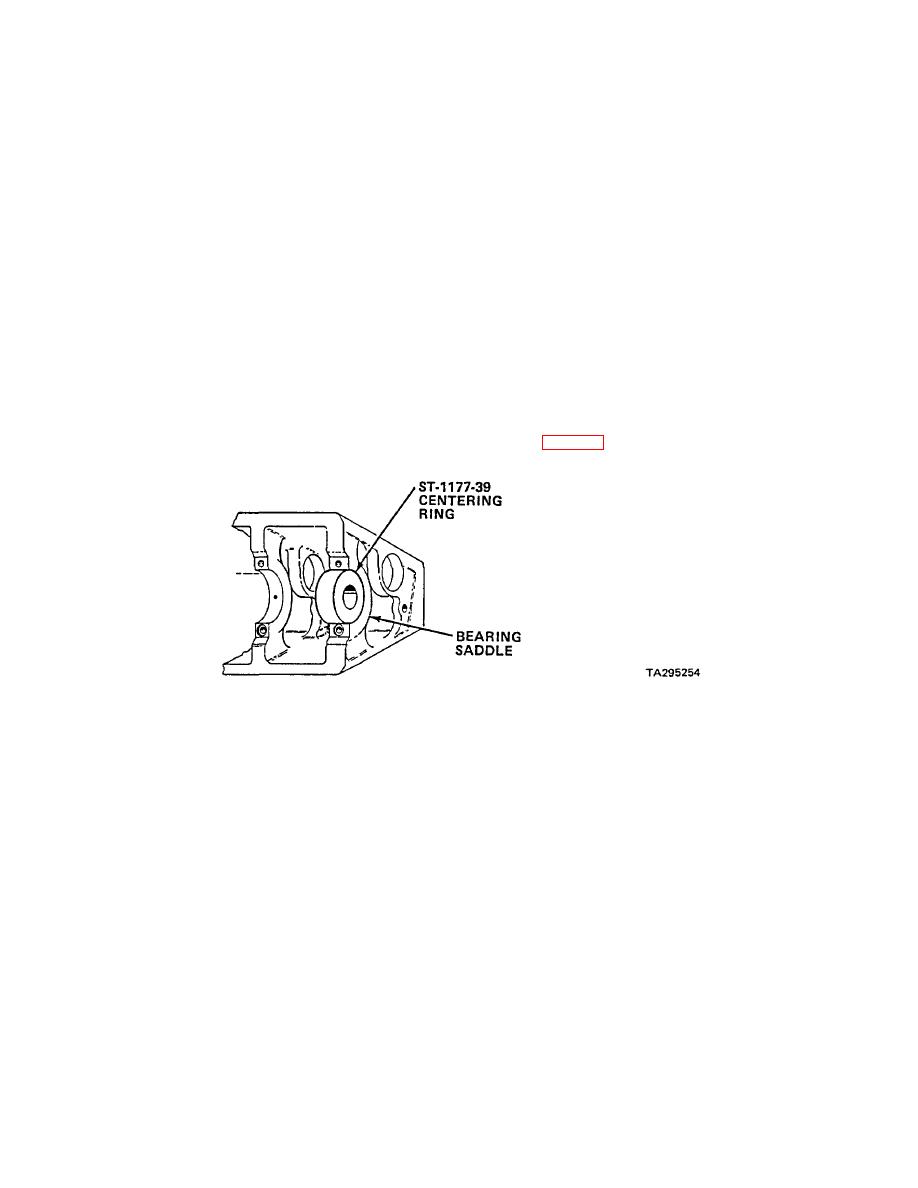

g. Main bearing line boring.

NOTE

Replacement main bearing caps are not machine finished. They are furnished with

0.015 in. (0.381 mm) excess material in bore. They must be machined to their

respective bearing saddles to ensure proper bearing shell fit. Line boring is also

required if bearing saddle is damaged, misalined, excessively tapered, or exceeds

maximum diameter. Rebored saddles are then fit with salvage sleeves. Sleeves

are then bored to accept standard bearing shells.

(1) Install boring bar.

(a) Remove two main bearing caps which do not require boring. Select two caps which are at each end

of cylinder block or as far apart as possible.

(b) If two caps cannot be selected which are far apart from each other, bridges must be installed to

provide boring bar with required support and stability (para 3-9i).

(c) Install ST-1177-39 centerin g rings in center of bearing saddles.

Tap in position with soft head

hammer.

NOTE

Caps fit tightly to provide proper seating.

(d) Assemble two main bearing caps with centering rings in saddles and torque capscrews as specified

in para 3-94e.

(e) Assemble new caps as required and torque to specifications.

(f) Lubricate centering rings and boring bar with engine oil.

(g) Slide boring bar through centering rings in block.

3-91

|

||

|

||