| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-1

(m) Check thrust surface after each cut to ensure proper finish is attained.

(n) Remove T-handle drive assembly.

(o) Remove depth setting collar assembly.

(p) Remove tool bit holder.

(q) Remove boring bar and centering rings.

(r) Clean thrust bearing area.

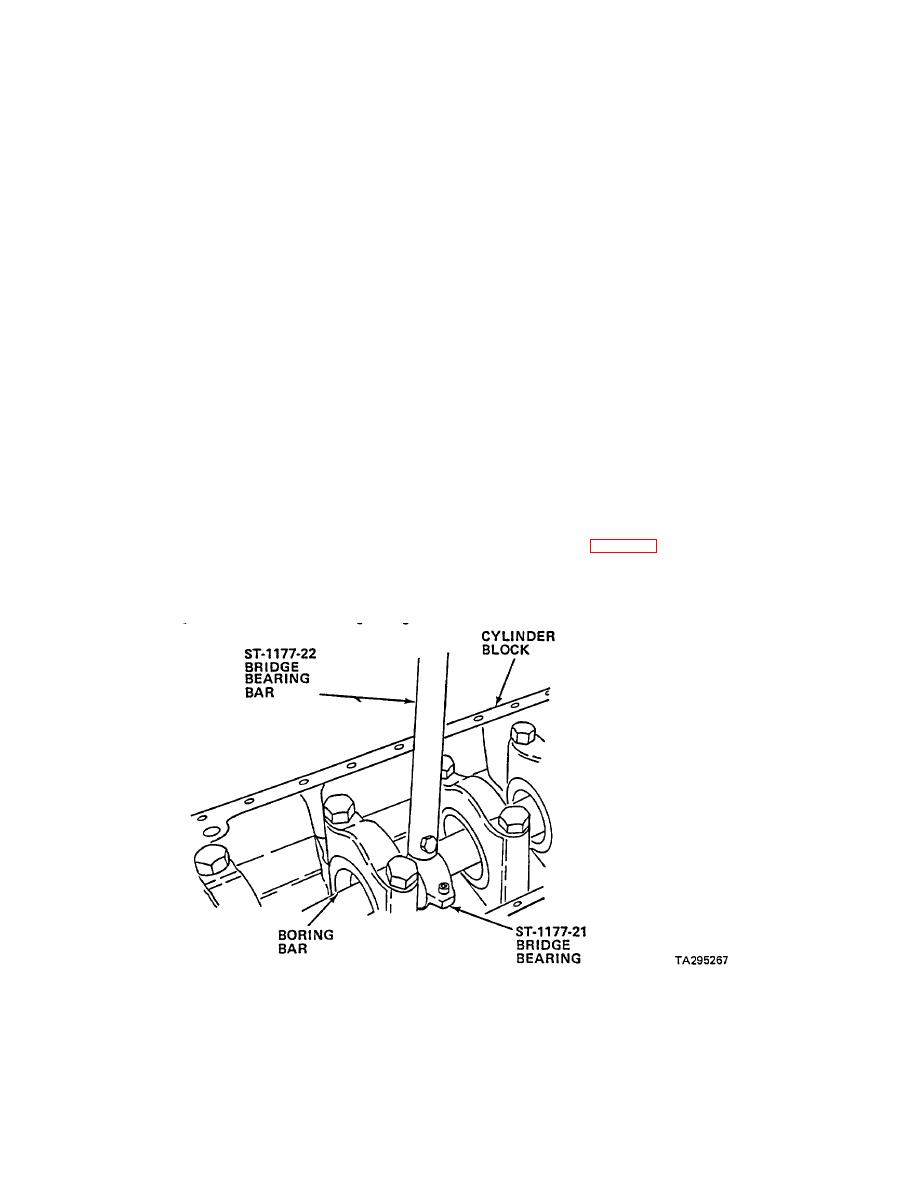

i. Boring bar bridges installation.

NOTE

If centering rings cannot be placed equally apart because of main bearing saddle

damage, bridges are available. These bridges support boring bar while saddle

bores are checked and/or machined.

(1) Install centering rings in undamaged main bearing saddles as far apart as possible.

(2) Install main bearing caps and torque capscrews to specifications in table 3-3.

(3) Slide boring bar into centering rings.

(4) Slide ST-1177-21 bridge bearing with ST-1177-22 bridge bearing bar over boring bar. Stop at point where

support is needed. Allow room for cutter holder if bridge bearing is next to journal to be cut.

3-104

|

||

|

||