| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-2

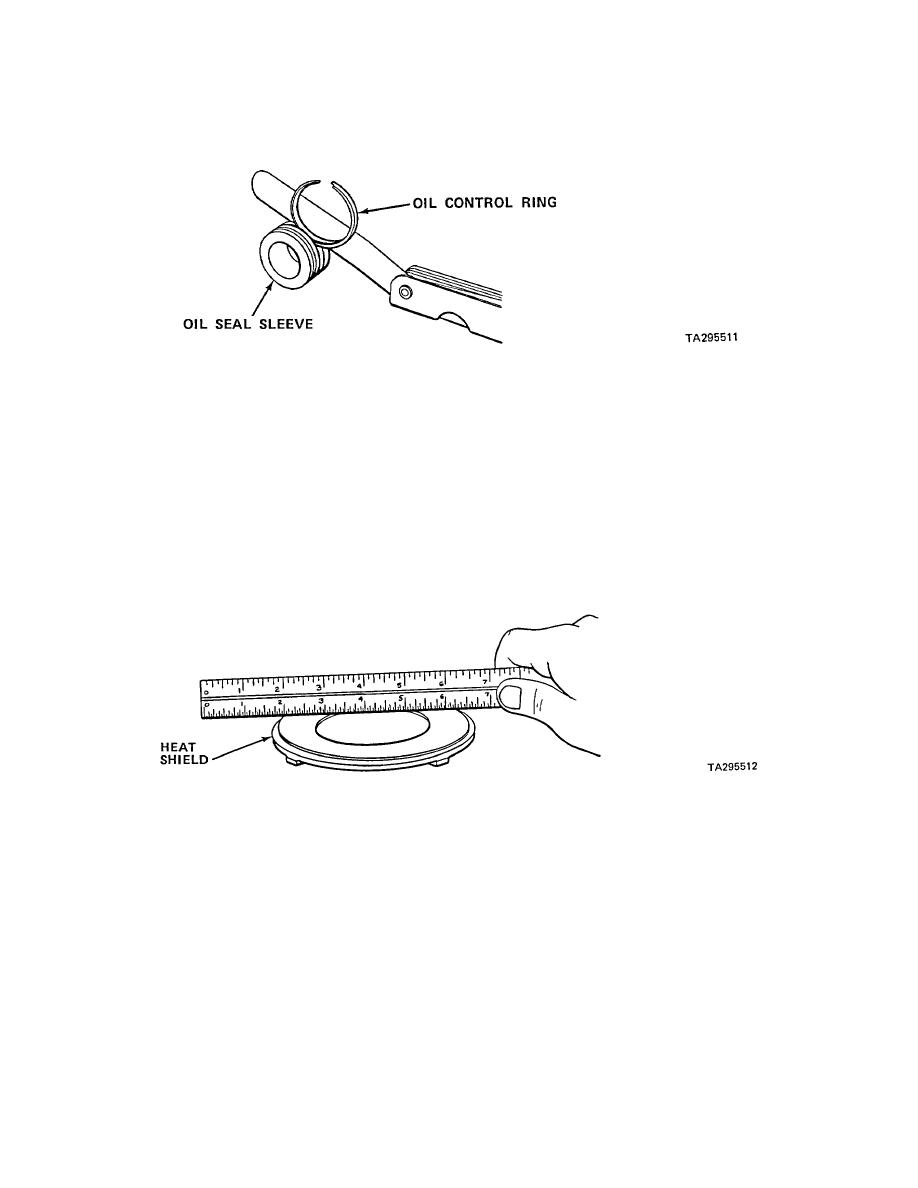

j. Inspect oil seal sleeve.

(1) Insert new oil control ring into groove of oil seal sleeve as shown. If clearance between ring and groove exceeds

0.009 in. (0.228 mm), replace sleeve.

(2) Measure width of groove. New part limit is 0.125 in. (3.175 mm). Replace sleeve if width exceeds 0.131 in.

(3.327 mm).

(3) Measure width of oil control ring. New part limit is 0.122 in. (3.109 mm). Replace if width exceeds 0.124 in.

(3.149 mm).

k. Inspect heat shield.

(1) Inspect for cracks. Replace if cracked.

(2) With straightedge, check for distortions. Replace if distorted.

l. Inspect compressor wheel.

NOTE

Compressor wheel must be replaced if vanes are cracked, broken, or have touched

compressor housing.

(1) Perform crack inspection using dye penetrant method. Replace if vanes cracked.

(2) Check for vane damage due to contact with compressor housing. Replace if damaged.

3-383

|

||

|

||