| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-2

(4)

Secure dial indicator to stud installed in block next to oil pump drive gear.

(5)

Position indicator pin against pump drive gear tooth.

(6)

Rotate gear to right as far as it will move to take up backlash. Hold gear in that position.

(7)

Zero indicator.

(8)

Rotate gear to left as far as it will move.

(9)

Read backlash on indicator.

(10)

Replace oil pump drive gear if backlash less than 0.0045 in. (0.1143 mm) or more than 0.105 in.

(0.266 mm).

(11)

Apply thread sealant to oil pressure signal tube 90 degrees elbow and install elbow in side of

cylinder block.

(12)

Apply thread sealant to oil pressure signal fitting on oil pump and elbow in block.

(13)

Secure oil pressure signal line to pump fitting and elbow on cylinder block.

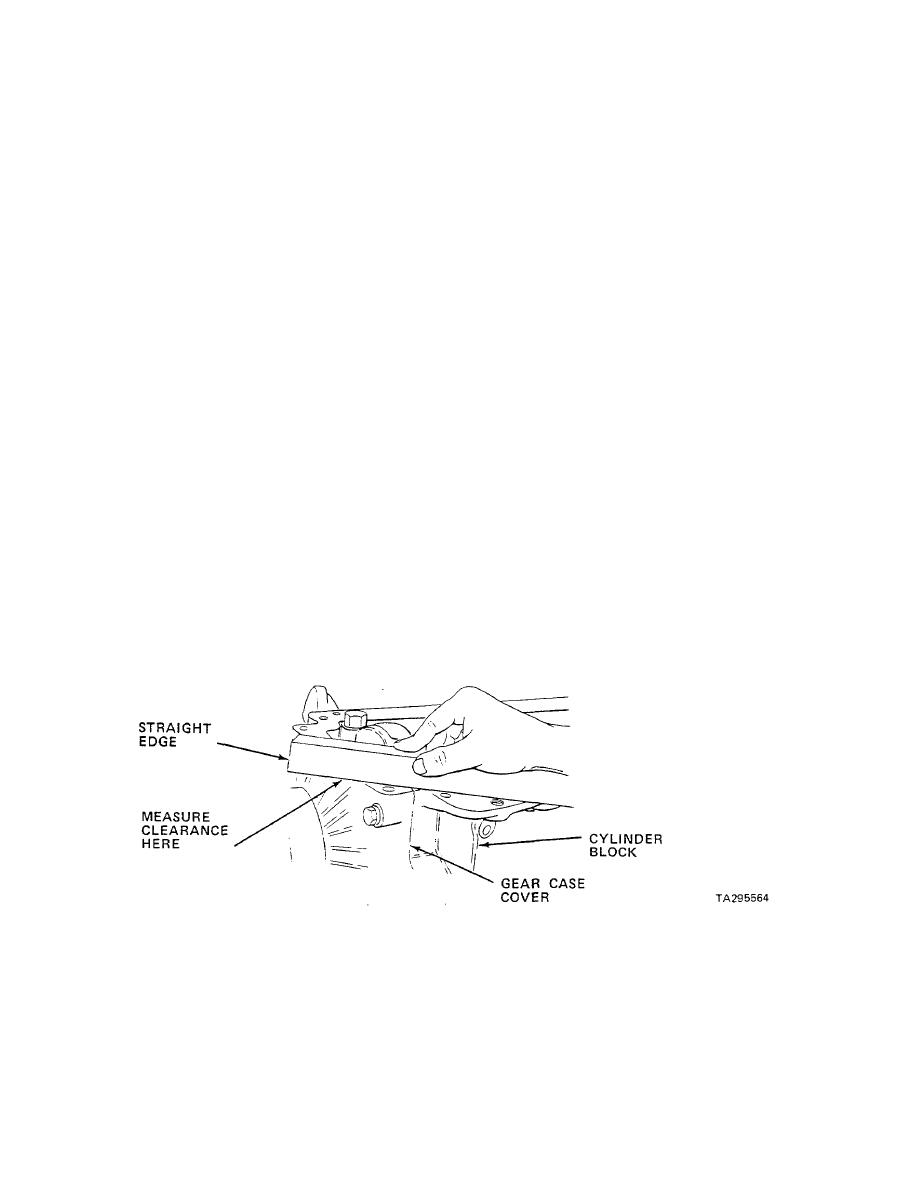

q.

Install front gear case cover.

(1)

Apply gasket sealant to gear case cover mounting flange and cylinder block mating surface.

(2)

Place new gasket on gear case cover and place case cover in position over alinement dowel pin.

(3)

Secure case cover with capscrews and washers. Torque capscrews to 45 - 50 ft lbs (61 - 68

Nm).

(4)

Trim off excess gasket material at pan flange mounting area.

(5)

With feeler gage and steel straight edge, measure distance between oil pan surface of block and

bottom surface of case cover.

3-435

|

||

|

||