TM 9--2815--247--34

0069 00--9

PISTONS, RINGS, AND ASSOCIATED PARTS REPAIR -- CONTINUED

0069 00

Inspection -- Continued

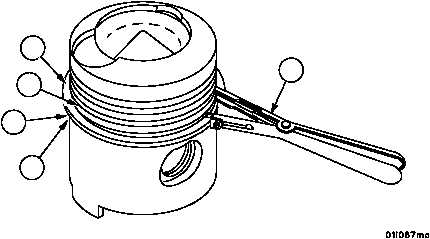

14. Insert remover and replacer (9) in end gap of oil control ring (4) and install in bottom piston ring groove (8).

15. Install compression ring (3) in piston ring groove (7) in the same manner.

Figure 8

4

7

8

9

HIDDEN

HIDDEN

3

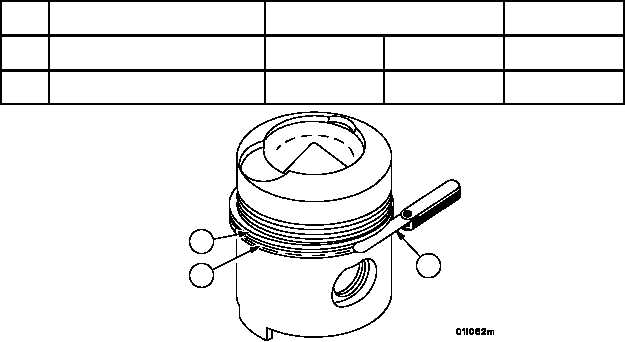

NOTE

Excessive side clearance indicates worn rings and/or worn pis-

ton grooves. Less than normal clearance indicates probable

damage or breakage at the ring land.

16. Measure side clearance of the bottom two rings (3 and 4) with thickness gauge (22). Mark rings for replacement

that do not meet the following limits.

REF

NO.

POINT OF MEASUREMENT

SIZES AND FITS OF NEW PARTS

inches(mm)

WEAR LIMITS

3

Side clearance between interme--

diate compression ring and piston

0.0045 (0.1143)

0.0025 (0.0635)

0.0100 (0.254)

4

Side clearance between oil control

ring and piston

0.0035 (0.0889)

0.0015 (0.0381)

0.0055 (0.1397)

Figure 8

3

4

24

|

|