ARMY TM 9-2815-252-24

AIR FORCE TO 38G1-92-2

g. Service lubrication system, refer to end item lubrication order.

h. Operate engine and check for proper operation and for leakage.

3-22. ENGINE OIL PRFSSURE TEST.

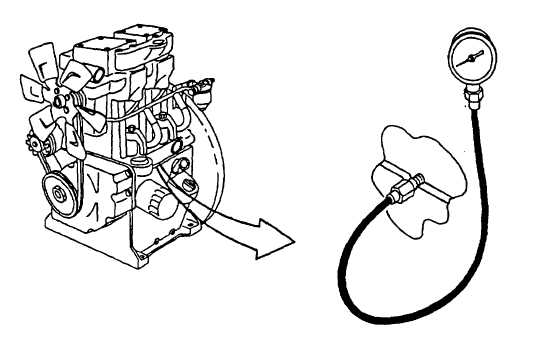

a. Tag and disconnect electrical leads to oil pressure sender, remove oil pressure sender, and install test

pressure gage 0-150 psi (01034 kPa), refer to FIGURE 3-18.

FIGURE 3-18. Oil Pressure Test Setup

b. Start engine and check oil pressure.

c. Remove oil pressure gage and install oil pressure sender.

d. Install electrical connectors. Remove tags.

e. Engine oil pressure should be 36 psi (248 kPa) at 1800 rpm.

Section VIII. GOVERNOR SYSTEM MAINTENANCE

3-23. GOVERNOR SYSTEM.

3-23.1. Removal.

a. Remove fuel injection pumps, refer to paragraph 3-13.1.

b. Remove gear end cover, refer to paragraph 3-28.1.

c. Unhook speeder spring (1, FIGURE 3-19) from retainer (2) and lever (29); remove spring.

d. Unhook spring (3) from pivot pin (4).

e. Remove lower pivot pin (4) from lower pivot support (5) and governor lever (6). Remove pivot retainer (7).

Remove spring (3) from lower pivot support (5).

f. Remove upper pivot pin (8) from upper pivot support (9) and governor lever (6). Remove pivot retainer (10).

Use care to retain all end play shims (11) that are installed.

3-40

|

|