ARMY TM 9-2815-252-24

AIR FORCE TO 38G1-92-2

NOTE

If pinion gear is worn or damaged, inspect flywheel ring gear also.

f. Inspect armature shaft gear, bearings, reduction gear, and pinion gear for wear or damage. Replace any part

that is damaged.

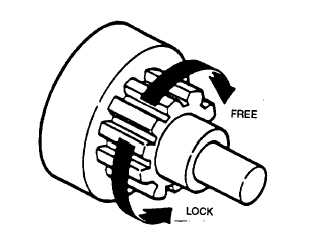

g. When pinion gear Is placed upon overrunning clutch, pinion gear should turn freely in one direction and lock

when turned in opposite direction, refer to FIGURE 3-25.

3-24.5. Assembly.

a. Apply a light coating of general purpose grease (630AA) to following starter components before assembling.

(1) Armature (8, FIGURE 3-22) shaft gear.

FIGURE 3-25. Overrunning Clutch

(2) Gear (18).

(3) Armature shaft bearings.

(4) Stopper (24).

(5) Sleeve bearing in front bracket (16).

(6) Pinion gear (25).

(7) Lever (21) sliding portion.

(8) Solenoid (1) plunger.

b. Position overrunning clutch (22) into front bracket (16).

c. Install spring (26) and pinion gear (25) on overrunning clutch shaft.

d. Slide stopper (24) onto shaft and install new retaining ring (23) in groove. Stopper (24) must fully engage

retaining ring when installed.

e. Install lever (21) (as noted during removal), spring set (19), and packing (20).

f. Adjust pinion shaft end play as follows:

(1) Place gear (18) on pinion shaft.

(2) Install center bracket (15) and secure with screw (14).

(3) Install new gasket (13), washer (12), and new retaining ring (11).

(4) Measure pinion shaft end play with a feeler gage between center bracket (15) and washer (12).

3-50

|

|