ARMY TM 9-2815-253-24

AIR FORCE TO 38G1-93-2

MARINE CORPS TM 2815-24/3

SECTION VI. FUEL SYSTEM MAINTENANCE

3-11. GENERAL.

This section provides maintenance for fuel system components. Components of the fuel system not mentioned in

this, section can be found in end item maintenance manual. Observe the following precautions:

a.

Always cap fuel connections after removal to prevent contamination.

b.

When priming or checking fuel pump timing, care must be taken to wipe spilled fuel from outside of engine.

c.

Special care must be taken to see that no leakage exists from fuel pipe connections on pump.

d.

When tightening or loosening fuel pump delivery connections, use two wrenches to prevent pump from twisting

on its seating and causing misalignment of pump calibration.

e.

When installing fuel pipe from pump to injector, fuel pipe must be correctly aligned and line up freely at both

ends. Do not pry on pipe to install, or leakage may result.

3-12. BLEEDING/PRIMING FUEL SYSTEM.

The following procedure is performed with engine running or cranking and repeated at each fuel pump.

a.

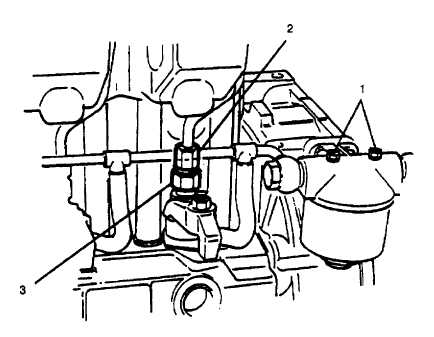

Loosen two screws (1, FIGURE 3-5) on fuel filter to allow air to escape. Tighten screws.

b.

Loosen injector fuel pipe (2) at fuel injection pump.

c.

Loosen delivery valve holder (3) on fuel injection pump up to a quarter of a turn until no air bubbles are expelled.

d.

Tighten delivery valve holder (3) using 17 mm crowsfoot wrench to 35 ft-lbs (47.5 NM).

e.

Tighten injector pipe nut (2) to 21 ft-lbs (28.5 Nm).

FIGURE 3-5. Priming Fuel System

3-18

|

|