ARMY TM 9-2815-254-24

AIR FORCE TO 38G1-94-2

(2)

(3)

(4)

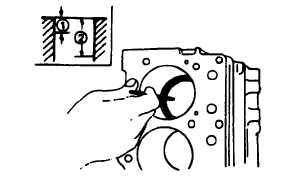

Using an inverted piston, push piston ring into cylinder liner approximately 0.39 in. (10 mm) or to the point

where diameter of liner is smallest.

Using a feeler gage, measure piston ring gap. Standard gap for three compression rings is 0.0079 to

0.0158 in. (0.2 to 0.4 mm). Standard gap for oil ring is 0.0039 to 0.0118 in. (0.1 to 0.3 mm) The limit for

gap is 0.0591 in. (1.5 mm), refer to FIGURE 3-82.

Inspect piston ring groove for damage or distortion. If damage or distortion is found, replace piston.

FIGURE 3-82. Measuring Piston Ring Gap

c.

Using a micrometer, measure piston pin OD at several points. Standard OD is 1.063 in. (27.0 mm), with a

limit d 1.062 in. (26.97 mm). If OD is less than limit, replace piston pm.

d.

Check piston pin and piston clearance as follows:

(1) Use an inside micrometer to measure piston pin hole in piston.

(2) Stand& piston pin hole ID is 1.0525 to 1.0628 in. (26.938 to 25.997 mm). The clearance limit between

pin and pin hole is 0.0 to 0.0002 in. (0.0 to 0.095 mm).

(3) lf clearance exceeds limit, replace raplace piston.

(4) Use an inside micrometer to measure small end bushings (20, FIGURE 3-77). Replace bushings if ID

is not within 1.0633 to 1.0635 in. (27.998 to 27.015 mm).

3-133

|

|