ARMY TM 9-2815-254-24

AIR FORCE TO 36G1-94-2

j.

Apply a coat of silicon adhesive (564R46001101) to cylinder block fitting surface for No. 1 and No. 5 bearing

cap.

k.

Install No. 1 and No. 5 bearing caps and ensure arch gasket makes firm contact with cylinder block side.

I.

Install remaining bearing caps with bearing cap head arrow mark facing forward. Bearing cap stamped with

a letter (A, B, C, etc.) must be installed at the No. 2 position.

m. Apply a coat of engine lubricating oil (MIL-L-2104) to ten bearing cap bolts and install them in bearing caps

hand-tight.

n.

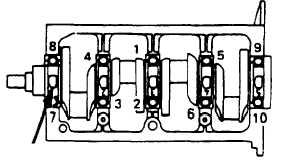

Tighten bearing cap bolts to 123.0 ft-lbs (166.6 Nm), a little at a time, in sequence shown in FIGURE 3-95.

FIGURE 8-95. Crankshaft Bearing Cap Bolts Tightening Sequence

o.

Ensure crankshaft turns smoothly by rotating it manually.

p.

Install rear oil seal (1, FIGURE 3-96) and spacer (2) as follows:

(1) Apply engine lubricating oil (MIL-L-2104) to oil seal (1) lip circumference.

(2) Apply silicon adhesive (564R46001101) to oil seal outer circumference.

(3) Place spacer (2) on oil seal (1).

(4) Using crankshaft rear oil seal installer (NU7627), install oil seal (1) cylinder block.

3-145

|

|