ARMY TM 9-2815-256-24

AIR FORCE TO 38G1-96-2

MARINE CORPS TM 2815-24/5

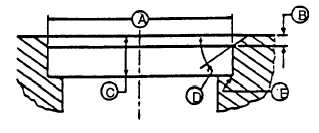

Exhaust Valve Seat Insert Bore Specifications:

A................................ ........................... 1.6570 to 1.6934 inches (42.087 to 43.013mm)

B................................ ................................ ...................0.150 inch (3.82 mm) Reference

C................................ ................................ .0.3557 to 0.3962 inch (9.036 to 10.064 mm)

D................................ ................................ ................................ ........... 38 to 42 degrees

E................................ ................................ ......... Maximum Radius 0.019 inch (0.5 mm)

Intake Valve Seat Insert Bore Specifications:

A................................ ........................... 1.8516 to 1.8545 inches (47.030 to 47.104 mm)

B................................ ................................ ...................0.136 inch (3.45 mm) Reference

C................................ ................................ .0.3557 to 0.3962 inch (9.036 to 10.064 mm)

D................................ ................................ ................................ ........... 38 to 42 degrees

E................................ ................................ ......... Maximum Radius 0.019 inch (0.5 mm)

Replacement Valve Seat Insert OD:

Intake................................ .................... 1.8565 to 1.8575 inches (47.155 to 47.181 mm)

Exhaust................................ ................. 1.6944 to 1.6954 inches (43.038 to 43.064 mm)

FIGURE 3-122. Valve Seat Bore Specifications

3-34.6. Inspect and Measure Before Installation.

a. After grinding valve seats, install refaced or new valves in cylinder head and check valve recess in accordance

with paragraph 3-34.2.

b. Inspect cylinder head capscrews for corrosion damage and overall condition of threads. Any caps crew with

corrosion or other defects must be replaced.

c. Check ventilator outlet hose on rocker arm cover for bent or damaged condition. Replace if necessary. Clean

ventilator hose and tube if they are restricted.

d.

Clean and inspect top deck of cylinder block as follows:

(1) Remove all old gasket material, corrosion, carbon, and other foreign material from top deck. Gasket surface

must be clean.

WARNING

Cleaning solvent is flammable and toxic to eyes, skin, and respiratory tract. Skin/eye protection

required. Avoid repeated/prolonged contact. Good general ventilation is normally adequate.

3-155

|

|