ARMY TM 9-2815-256-24

AIR FORCE TO 38G1-96-2

MARINE CORPS TM 2815-24/5

CAUTION

Make sure packing is not twisted, otherwise poor sealing and equipment damage will occur.

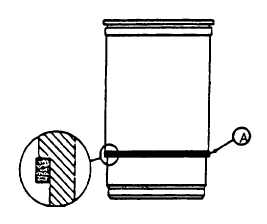

FIGURE 3-166. Location of Cylinder Liner Square Packing

e.

Slide packing down firmly against shoulder on liner.

f.

Coat liner packings (A and B, FIGURE 3-165), sealing area of the cylinder liner and engine block packing

(A, FIGURE 3-166) with liner lubricant.

g.

Carefully place cylinder liner, with packing installed, into cylinder block bore. Do not scuff packing across

upper bore.

CAUTION:

When OD of liners are pitted or eroded, but still within the acceptable service limit, rotate liners 90

degrees from their removed position. Rotate pitted section of liner either toward front or rear of

engine. If liners are not pitted or eroded, rotation will not be necessary. Install liners with mark

toward the front of engine.

NOTE

A resistance will be felt when cylinder liner is aligned in pilot bore.

h.

Seat liners (9, FIGURE 3-143) with wood block and hammer.

i.

Cylinder liner (9) will protrude over top of cylinder block more than normal due to uncompressed packings.

CAUTION

If you suspect that a packing may have sheared or displaced while installing liner, remove and

examine liner and packing assembly. If no damage is found, check packings for proper position,

relubricate packings and reinstall liner assembly.

j.

With liners installed, hold in place with large flatwashers and capscrews, refer to FIGURE 3-140. Turn

capscrews snug but do not tighten.

3-213

|

|