ARMY TM 9-2815-256-24

AIR FORCE TO 38G1-96-2

MARINE CORPS TM 2815-24/5

3-7. INTAKE MANIFOLD PRESSURE CHECK.

a.

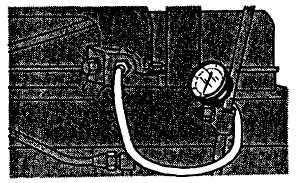

Remove plug from intake manifold and connect suitable gage to intake manifold, refer to FIGURE 3-1.

FIGURE 3-1. Connecting Test Gage to Intake Manifold

b.

Run engine to bring up to normal operating temperature.(From a cold start, operate engine 10 to 15 minutes at

slow idle.)

NOTE

Engine speed and load should be stabilized before taking readings on gage. Be sure that gage works

properly.

NOTE

Pressure checks are only a guide to determine if there is an engine problem (valve leakage,

defective nozzles, etc). Low readings are not a valid reason for increasing injection pump fuel

delivery. Pump adjustment should be within specification.

c.

Observe pressure reading on gage. Reading should be at least 9 psi (60 kPa/0.6 bar) when engine is developing

rated power at full load rated speed.

d.

If boost pressure is too high, remove and test fuel injection pump for high fuel delivery.

e.

If boost pressure is too low, check for the following:

(1)

Restricted air filter elements.

(2)

Restricted fuel filter elements.

(3)

Incorrect fast idle adjustment.

(4)

Incorrect injection pump timing.

(5)

Exhaust manifold leaks.

(6)

Intake manifold leaks.

(7)

Faulty fuel transfer pump.

3-19

|

|