ARMY TM 9-2815-257-24

AIR FORCE TO 38G1-128-2

MARINE CORPS TM 10155A/2815-24/3

4-19

4-11. FUEL INJECTION PUMP MAINTENANCE - cont.

4.

Adjust fuel injection timing in accordance with

step E before connecting fuel pipe (1) to injection

pump (2).

E. FUEL INJECTION TIMING ADJUSTMENT.

1.

Remove flywheel housing (Para. 3-13). Dis-

connect fuel pipe (1, Figure 4-12) from injection

pump (2).

2.

Set governor speed control handle to RUN

position.

3.

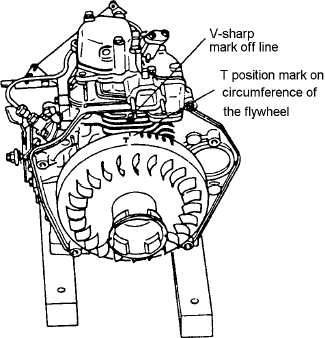

Rotate flywheel one revolution in the clockwise

direction until T position mark on flywheel

matches V mark off line on cylinder body fin (see

Figure 4-13). This is the top dead center (TDC)

position. There should be some fuel coming out

of the fuel injection pump. If fuel is not present,

rotate the flywheel another revolution clockwise.

4.

Turn flywheel counter-clockwise about 30

degrees from T position mark.

5.

Slowly turn flywheel clockwise until fuel flows

from injection pump, then stop rotation.

6.

Use timing marks on flywheel to determine

flywheel position. Marks are 5 degrees apart.

Flywheel should be 16 to 18 degrees before TDC

position. Therefore, the V mark off line should

be aligned between the third and fourth flywheel

timing marks before the TDC position mark.

7.

Repeat steps 4 through 6 two or three times to

make sure reading is accurate. Fuel injection

should begin when flywheel is rotated 16 to 18

degrees from TDC position mark.

Figure 4-13. Fuel Injection Timing

|

|