ARMY TM 9-2815-257-24

AIR FORCE TO 38G1-128-2

MARINE CORPS TM 10155A/2815-24/3

5-10

5-7. CRANKSHAFT ASSEMBLY MAINTENANCE - cont.

C. INSPECTION.

1.

Inspect flywheel (10, Figure 5-1) for cracks, deformation, or obvious damage. Inspect for broken, chipped,

or cracked flywheel fins. Replace flywheel if damaged.

2.

Inspect flywheel housing seal (6) for deterioration or permanent set. Replace if damaged or deformed.

3.

Inspect crankshaft (5, Figure 5-5) for cracks, deformation, or obvious damage. Replace crankshaft if

cracked or damaged.

4.

Inspect gears (7, 8) for broken, chipped, or worn teeth. Replace gears and crankshaft (5) as an assembly if

a gear is damaged or worn.

5.

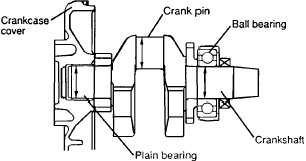

Measure the outside diameter (OD) of crankshaft crank pin (Figure 5-3). OD must be 1.4134 inches

(35.90 mm), minimum. Replace crankshaft assembly if out of limits.

6.

Measure the OD of crankshaft where crankshaft mates to crankcase cover plain bearing (Figure 5-3). OD

must be 1.3744 inches (34.91 mm), minimum. Replace crankshaft assembly if out of limits.

7.

Measure the OD of crankshaft where it mates to

flywheel side ball bearing (Figure 5-3). OD must

be 1.3782 inches (35.01 mm), minimum.

Replace crankshaft assembly if out of limits.

8.

Bearing (6, Figure 5-5) is press fit onto crankshaft

(5). Check bearing for looseness. Replace

crankshaft assembly if bearing is loose.

9.

Inspect bearing (4) for discoloration, separation,

or any other obvious damage. Remove and

replace bearing if damaged in any way.

Figure 5-3. Crankshaft Inspection

|

|