ARMY TM 9-2815-259-24

AIR FORCE TO 38G1-125-2

MARINE CORPS 09249A/09246A-24

5-63

c.

Inspection.

(1) Inspect crankshaft per the following procedures:

(a)

Clean crankshaft using solvent and compressed air.

(b)

Inspect oil passages to make sure they are open. Use compressed air and a small piece of

wire.

(c)

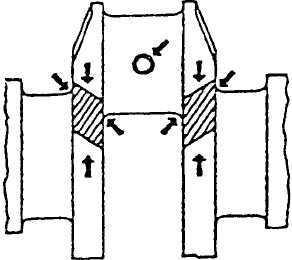

Inspect crankshaft for any signs of load stress, cracks, scoring, or scratches on journals. (An

inspection must be made if the crankshaft damper was found to be damaged or defective.)

Figure 5-68 shows critical areas of load stress in a crankshaft.

FIGURE 5-68. CRITICAL AREAS OF CRANKSHAFT LOAD STRESS

NOTE

When inspecting crankshaft for cracks, a method (such as the Fluorescent

Magnetic Particle Method) must be used that is capable of detecting minute

cracks that are not visible to the eye. This method magnetizes the crank,

employing magnetic particles which are fluorescent and glow under black

light. Replace crankshaft if cracks are found. The crankshaft must be

demagnetized after the test.

(d)

Check each journal for evidence of excessive overheating or discoloration. If either

condition exists, replace crankshaft since heat treatment has probably been destroyed.

|

|