TM 9-2920-243-34

c. Shift Housing Assembly.

(1) Inspect shift housing for cracks or

distortion and burs on mating flange and packing

surfaces. Replace if damaged.

(2) Inspect bushing-type bearing for score

marks and wear patterns. Check bearing against

limits specified in repair rebuild standards (para

3-31e) and replace (para 3-15c) if worn beyond

limits.

(3) If the bushing.type bearing is removed

from the shift housing, check diameter of bearing

bore against limits specified in repair and rebuild

standards (para 3-31e). Replace shift housing if

worn beyond limits.

d. Drive Assembly.

(1) Inspect bearing surface and drive

assembly internal splines for score marks and

wear patterns. Replace drive if worn or damaged.

(2) Check drive spring against limits

specified in repair and rebuild standards (para 3-

31a) and replace spring if it is not within these

limits.

(3) Inspect drive collar for signs of wear and

distortion and replace drive assembly if either

condition exists.

(4) Inspect gear teeth for wear pattern and

replace drive assembly if wear is excessive.

e. Brush Holder Assemblies and Brushes.

(1) Inspect brush holder and spring

assemblies for any visible damage. Replace if

damaged. Check brush spring tension with a 0 to

40 ounce spring scale. It should require ap-

proximately 36 ounces to lift end of spring out of

brush holder. If tension is less than 30 ounces,

replace holder and spring assembly.

(2) Inspect brushes for chips, cracks, loose

terminal leads, and grease spots. Check length of

brushes against limits specified in repair and

rebuild standards (para 3-31a.). Replace brushes

if worn beyond these limits.

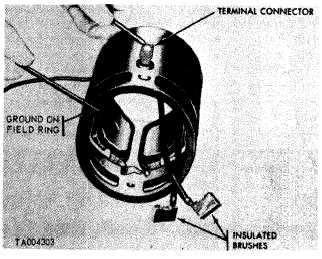

f. Field Ring Assembly.

(1) Check field coils for insulation breakdown

with an ohmmeter. Attach one probe of ohmmeter

to field coil terminal and the other probe to field

ring (fig. 3-25). The minimum reading should not

be less than one megohm. If field coils are

damaged, replace starter.

(2) Inspect field frame for cracks and burs.

Replace starter if cracked.

Figure 3-25. Testing field coils for grounds.

g. Armature Assembly.

(1) Inspect commutator contact surface of

armature. A satisfactory condition is indicated by

an even, highly burnished, dark-copper color. If

contact surface is rough, pitted, scored, burned,

or coated with hard carbon or oil, commutator

must be cleaned or resurfaced as necessary,

provided it is in good electrical and mechanical

condition as a result of following inspection.

Check armature against limits specified in repair

and rebuild standards (para 3-31 a) and replace

starter if it is not within these limits. Inspect

splines of armature shaft for wear or damage and

replace starter if either condition exists.

(2) Inspect armature for grounds with a test

light by touching one probe to commutator bar

riser and other to armature core (fig. 3-26). Test

all commutator bars in this manner. If test light

glows, armature is grounded and starter must be

replaced.

(3) Inspect armature for short circuits with a

growler. Place armature in growler and hold a

thin strip of steel, such as a hacksaw blade, about

1/32 to 1/16-inch away from armature core as

shown in figure 3-27. While holding steel strip in

position, rotate armature slowly in growler. A

short circuit will pull the steep strip tightly

against armature core and cause strip to vibrate.

If a short circuit is found, starter must be

replaced.

3-10

|

|