| Tweet |

Custom Search

|

|

|

||

TM 9-8000

(2) Providing a flange at the top of the block

that locks the sleeve in place when the cylinder

head is bolted into place. This is more desirable

than a friction fit, because it locks the sleeve

tightly.

(3) Casting the sleeve into the cylinder

wall. This is a popular means of securing the

sleeve in an aluminum block.

Whatever method is used to secure the sleeve, it is

very important that the sleeve fits tightly. This is

important so that the sleeve may transfer its heat

effectively to the water jackets.

e. Crankcase (Fig. 3-4). The crankcase is

the part of the cylinder block that supports and

encloses the crankshaft. It is also where the

engine's lubricating oil is stored. The upper part

of the crankcase usually is part of the cylinder

block, while the lower part is removable. This

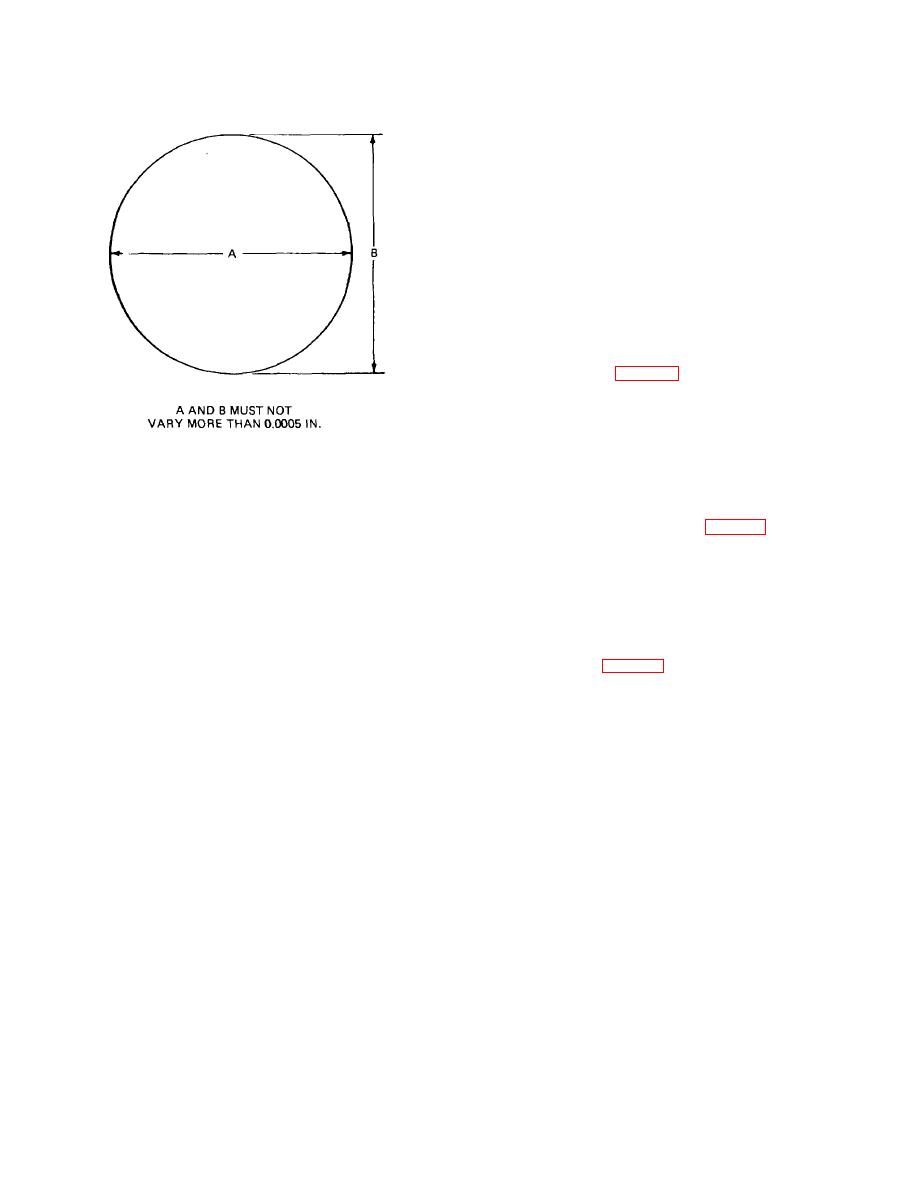

Figure 3-2. Requirements of a Cylinder.

removable lower part usually is called an oil pan,

and is made of cast aluminum or pressed steel.

This will increase engine life while keeping pro-

duction costs down.

f. Cooling and Lubrication (Fig. 3-1). The

cylinder block also provides the foundation for the

(2) Because the cylinders wear more than

cooling and the lubrication systems. It provides

any other area of the block, the life of the block can

the mountings for the pumps, and has the coolant

be extended greatly by using sleeves. When

and lubrication passages cast into it.

overhaul time comes, the block then can be

renewed by merely replacing the sleeves. For this

3-2. Cylinder Heads.

reason, sleeves are very popular in large diesel

engines, for which the blocks are very expensive.

a. General (Fig. 3-5). The cylinder head is a

(3) As stated in paragraph 3-lb., using a

separate one-piece casting that bolts to the top of

sleeve allows an engine to be made of a material

the cylinders on an air-cooled engine, or to the

such as aluminum by providing the wearing

top of the cylinder block on a liquid-cooled

qualities necessary for the cylinder that the

engine.

aluminum cannot.

b. Construction.

There are two types of cylinder sleeves: the wet

and the dry type. The dry type is a sleeve that

presses into a full cylinder that completely covers

(1) The cylinder heads on liquid-cooled

the water jacket. Because the sleeve has the block

engines have been made almost exclusively from

to support it, it can be very thin. The wet sleeve

cast iron until recent years. Due to weight

also presses Into the cylinder. The difference is

considerations that have become more Impor-

that the water jacket is open in the block and is

tant, a large percentage of cylinder heads now

completed by the sleeve. Because it gets no

are being made from aluminum.

central support from the block, the wet sleeve

must be made thicker than a dry sleeve. Also,,

(2) The cylinder heads on air-cooled en-

because the sleeve completes the water jacket, it

gines are made almost exclusively from alumi-

must fit so as to seal in the coolant. The following

num. This is due to the fact that aluminum will

are the three basic ways of securing the sleeves in

conduct heat approximately three times as fast as

the cylinder block:

cast iron. This is a critical consideration with air

cooling.

(1) Pressing in a sleeve that is tight enough

TA233352

to be held in by friction.

3-2

|

||

|

||