| Tweet |

Custom Search

|

|

|

||

TM 9-8000

Section II. ROTATING AND RECIPROCATING PARTS

reason, it has been found that aluminum is the

3-5.

Piston.

best material for piston construction. It has a very

high strength-to-weight ratio. In addition to

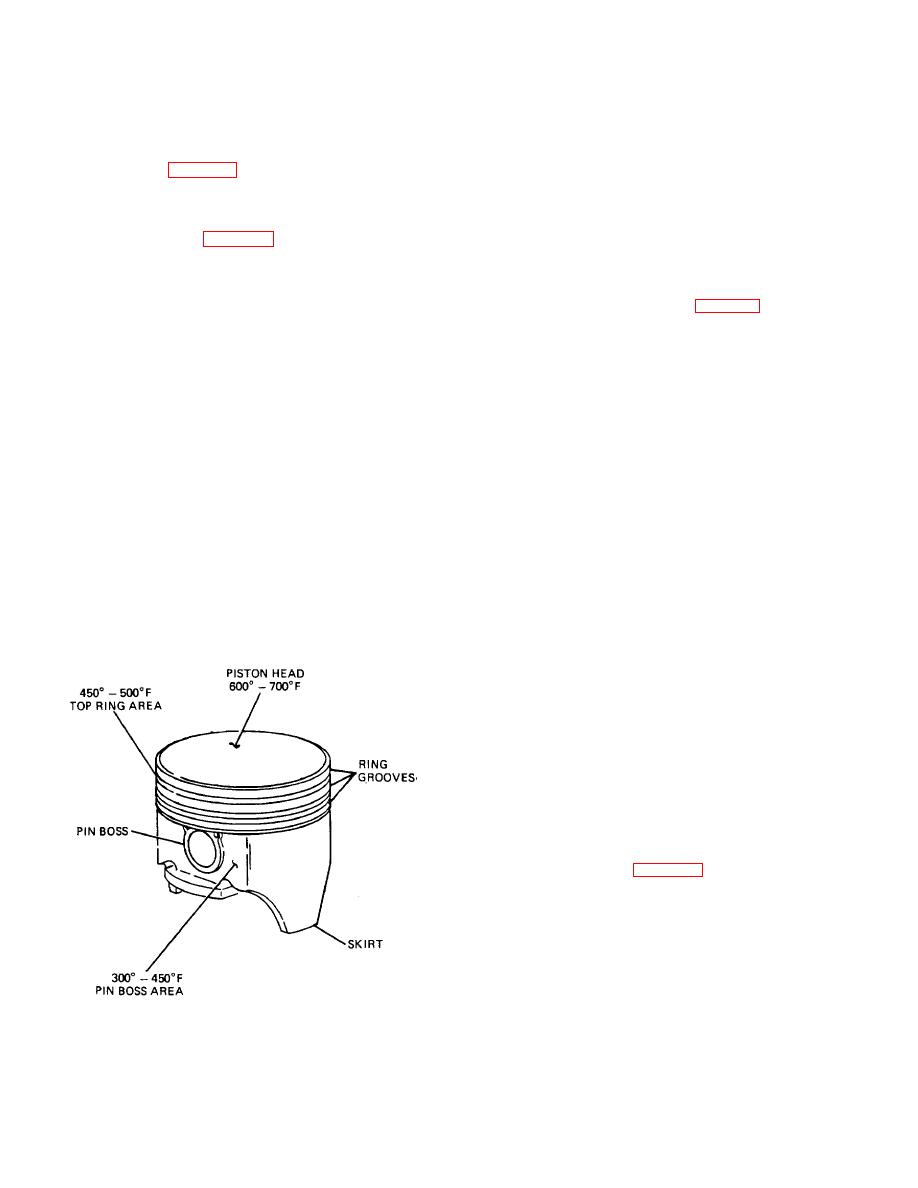

a. General (Fig. 3-12). The piston is the part

being lightweight, aluminum is an excellent

of the engine that receives the energy from the

conductor of heat and is machined easily. Pistons

combustion and transmits it to the crankshaft.

also are manufactured from cast iron. Cast iron

also is an excellent material for pistons in low-

b. Requirements (Fig. 3-12). The piston

speed engines. It is not suitable for high speeds

must withstand incredible punishment under se-

because it is a very heavy material.

vere temperature extremes. The following are

examples of conditions that a piston must with-

d. Controlling Expansion (Fig. 3-13). Pis-

stand at normal highway speeds.

tons must have features built into them to help

them control expansion. Without these features,

(1) As the piston moves from the top of the

pistons would fit loosely in the cylinders when

cylinder to the bottom (or vice versa), it ac-

cold, and then bind in the cylinders as they warm

celerates from a stop to a speed of approximately

up. This is a problem with aluminum, because it

50 mph (80 km/h) at midpoint, and then deceler-

expands so much. To control expansion, pistons

ates to a stop again. It does this approximately 80

may be designed with the following features:

times per second.

(1) It is obvious that the crown of the piston

(2) The piston is subjected to pressures on

will get hotter than the rest of the piston. To

its head in excess of 1000 psi (6895

prevent it from expanding to a larger size than the

kPa).

rest of the piston, it is machined to a diameter

that is approximately 0.03 to 0.04 in. (0.762 to

(3) The piston head is subjected to temper-

1.016 mm) smaller than the skirt area.

atures well over 600F (3160C).

(2) One of the ways to control expansion in

c. Construction Materials. When designing

the skirt area is to cut a slot up the side of the skirt.

pistons, weight is a major consideration. This is

As a split-skirt piston warms up, the split will

because of the tremendous inertial forces created

merely close up, thereby keeping the skirt from

by the rapid change in piston direction. For this

expanding outward and binding the piston in the

cylinder.

(3) Another variation of the split-skirt pis-

ton is the T-slot piston. The T-slot piston is sim-

ilar to the split-skirt piston with the addition of a

horizontal slot that retards heat transfer from the

piston head to the piston skirt.

(4) Some aluminum pistons have steel

braces cast into them to control

expansion.

e. Cam Grinding (Fig. 3-14). By making the

piston egg-shaped, it will be able to fit the cylinder

better throughout its operational temperature

range. A piston of this configuration is called a

cam-ground piston. Cam-ground pistons are

machined so that their diameter is smaller parallel

to the piston pin axis than it is perpendicular to it.

When the piston is cold, it will be big enough

TA233358

Figure 3-12. Piston

3-8

|

||

|

||