| Tweet |

Custom Search

|

|

|

||

TM 9-8000

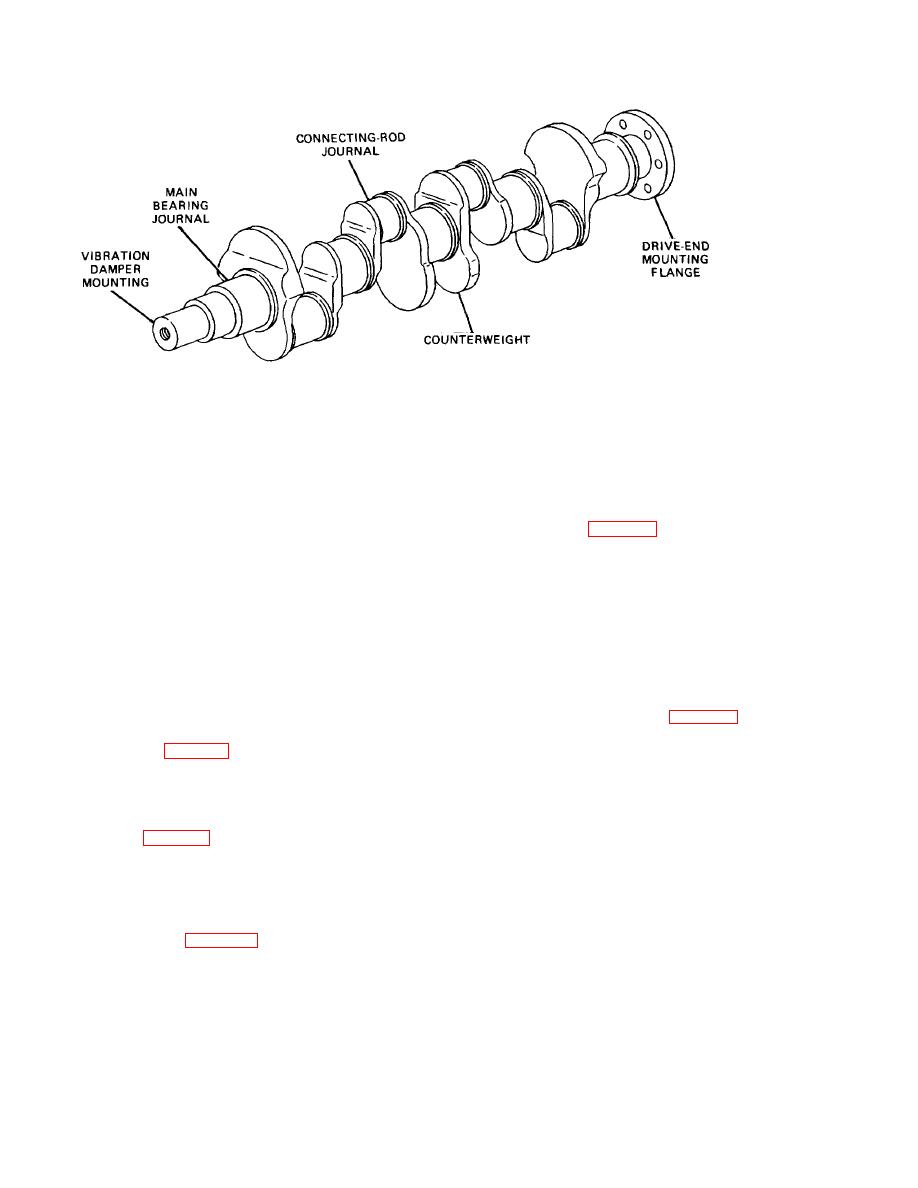

Figure 3-34. Crankshaft Construction.

vibration damper at the end of the crankshaft opposite

of the shells. When the halves are clamped together,

the output end will serve to absorb torsional vibration.

they form a precision bearing that will be a perfect fit for

There are a few variations of the vibration damper, but

a properly sized shaft. The bearing inserts and the

they all accomplish their task in basically the same

mating surface that hold them must be sized perfectly.

manner. They all employ a two-piece design. The

The insert merely slips into place and is held from turning

differences in design are in how the two pieces are

by the locating tab.

linked together. One type of damper links the pieces

c. Materials (Fig. 3-41). Most bearings begin with a

together by an adjustable friction clutch. Whenever a

sudden change in crankshaft speed occurs, it causes the

steel backing to give them rigidity. The lining then is

friction clutch to slip. This is because the outer section of

applied to the steel backing. The lining usually consists

the damper will tend to continue at the same speed. The

of an alloy of copper, tin, and lead. The lining also may

slippage of the clutch serves to absorb the torsional

be made of babbit. Babbit is a popular bearing material

vibration. Another type of damper links the two pieces

that is an alloy consisting of copper, tin, and antimony.

together with rubber. As the crankshaft speeds up, the

The lining thickness usually ranges from 0.002 to0.005

rubber compresses, storing energy. This serves to

in. (0.051 to 0.127 mm). The bearing then is coated with

minimize the effect of crankshaft speed increase. As the

either aluminum or tin to a thickness of approximately

crankshaft unwinds, the damper releases the energy

0.001 in. (0.025 mm).

stored in the compressed rubber to cushion the speed

d. Bearing Requirements (Fig. 3-42). Bearings must be

change in the other direction.

able to support the crankshaft rotation and deliver power-

e. Lubrication (Fig. 3-38). The crankshaft has internal

stroke thrusts under the most adverse conditions. A

drilled passages to supply lubrication to its bearings.

good bearing must have the following qualities.

3-10. Crankshaft Bearings.

subjected to tremendous forces from the thrust of the

power strokes. The bearings must be able to withstand

a. General (Fig. 3-39). The crankshaft is supported in

these loads without spreading out or cracking.

connecting rods are sup- ported on the crankshaft by the

(2) Corrosion. The bearing must be resistant to

rod bearings.

moisture and acids that always are present in the

TA233370

b. Construction (Fig. 3-40). Crankshaft bearings

are made as precision inserts. They simply slip into place

in the upper and lower halves

3-20

|

||

|

||