| Tweet |

Custom Search

|

|

|

||

TM 9-8000

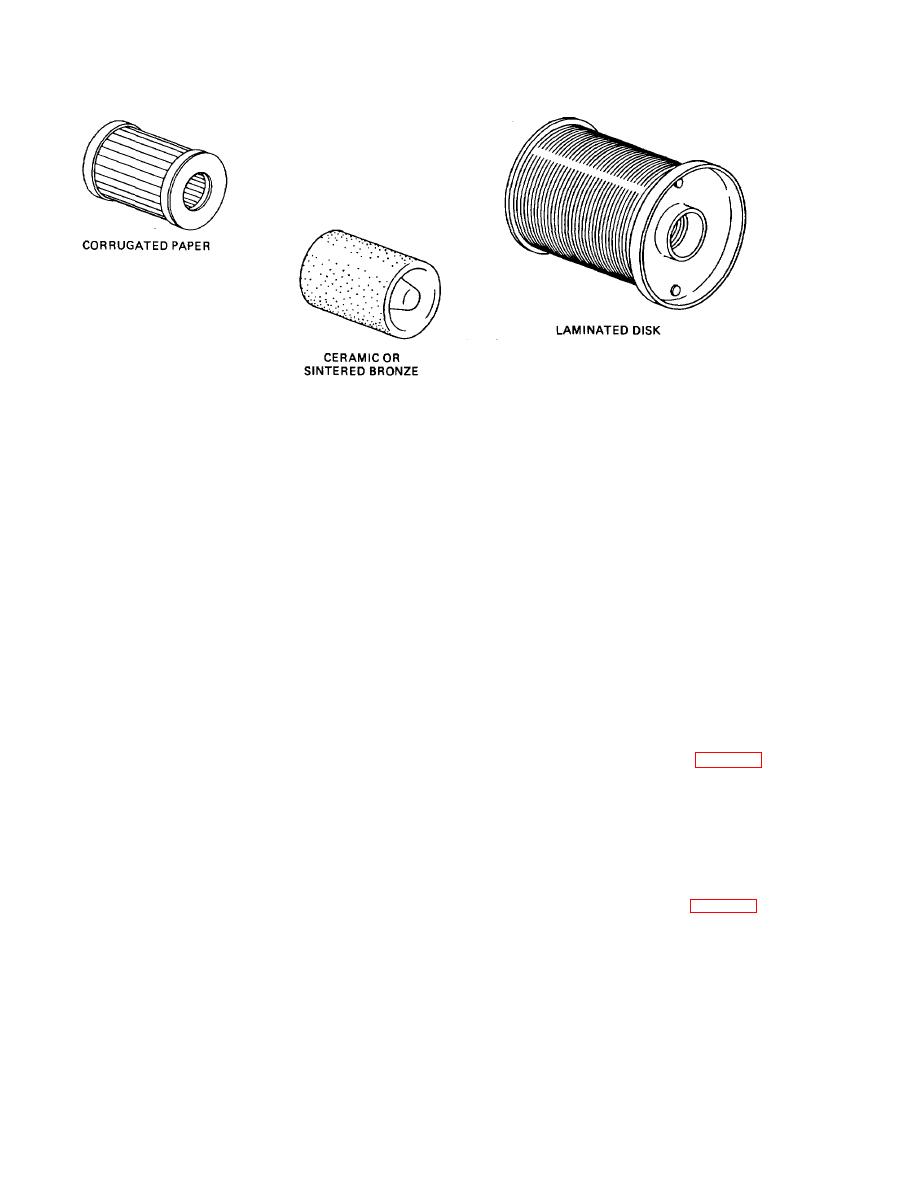

Figure 4-8. Fuel Filter Element Configurations.

]

(1) The rocker arm is moved up and down by the

nonpositive-type fuel pump regulates fuel line pressure.

engine camshaft. The rocker arm spring causes the

Normal pressures range from 1.5 to 6 psi (10.3 to 41.4

rocker arm to follow the cam lobe.

kPa). The operating range of the pump depends on the

tension exerted by the diaphragm spring.

(2) The rocker arm hooks into an elongated slot in

the

(8) A venthole is provided under the diaphragm to

pull rod. The other end of the pull rod is attached to

the

allow the pressure to change in the lower chamber as

diaphragm.

the diaphragm flexes.

(3) As the camshaft operates the rocker arm, it

will

operate the diaphragm against the force of

the

(9) The pulsation chamber, located above the pump

diaphragm spring.

chamber, uses a soft diaphragm and a sealed chamber

to cushion the pulsating action inherent to the

(4) As the rocker arm pulls the diaphragm down, the

diaphragm-type pump.

inlet check valve is unseated and fuel is drawn into the

pump chamber. The outlet check valve seals the outlet

(10) An oil seal is provided to keep crank-case oil from

passage.

entering the lower chamber and leaking from the

venthole.

(5) As the diaphragm spring pushes the diaphragm

back up, the inlet check valve seals the inlet and the fuel

d. Mechanical, Positive Type (Fig. 4-10).

in the pump chamber is pushed through the unseated

The positive-type mechanical pump operates in the

outlet check valve and through the pump outlet.

same manner as the nonpositive type. The difference is

that the diaphragm pull rod is solidly linked to the rocker

(6) The action is repeated each time the rocker arm

arm. The pump, therefore, will not regulate fuel line

operates the diaphragm.

pressure. When this type of pump is used, a separate

fuel pressure regulation device must be used that will

(7) Pressure will build in the fuel line and the pump

bypass excess fuel back to the fuel tank.

chamber as the fuel pump fills the carburetor bowl. As

the pressure rises to the desired level in the pump

e. Double Action Fuel Pump (Fig. 4-11).

chamber, it will hold the diaphragm down against the

Vehicles that use vacuum-operated windshield wipers

pressure of the diaphragm spring. The rocker arm will

often will utilize a supply pump that is built Into the fuel

move up and down in the slotted pull rod. There will be

pump. The pump serves to operate the windshield

no pumping action until the fuel line pressure again

wipers during periods of high engine load when manifold

drops below the desired level. In this way, the

vacuum is low (para 17-14). The pump operates from the

same

TA233390

4-5

|

||

|

||