| Tweet |

Custom Search

|

|

|

||

TM 9-8000

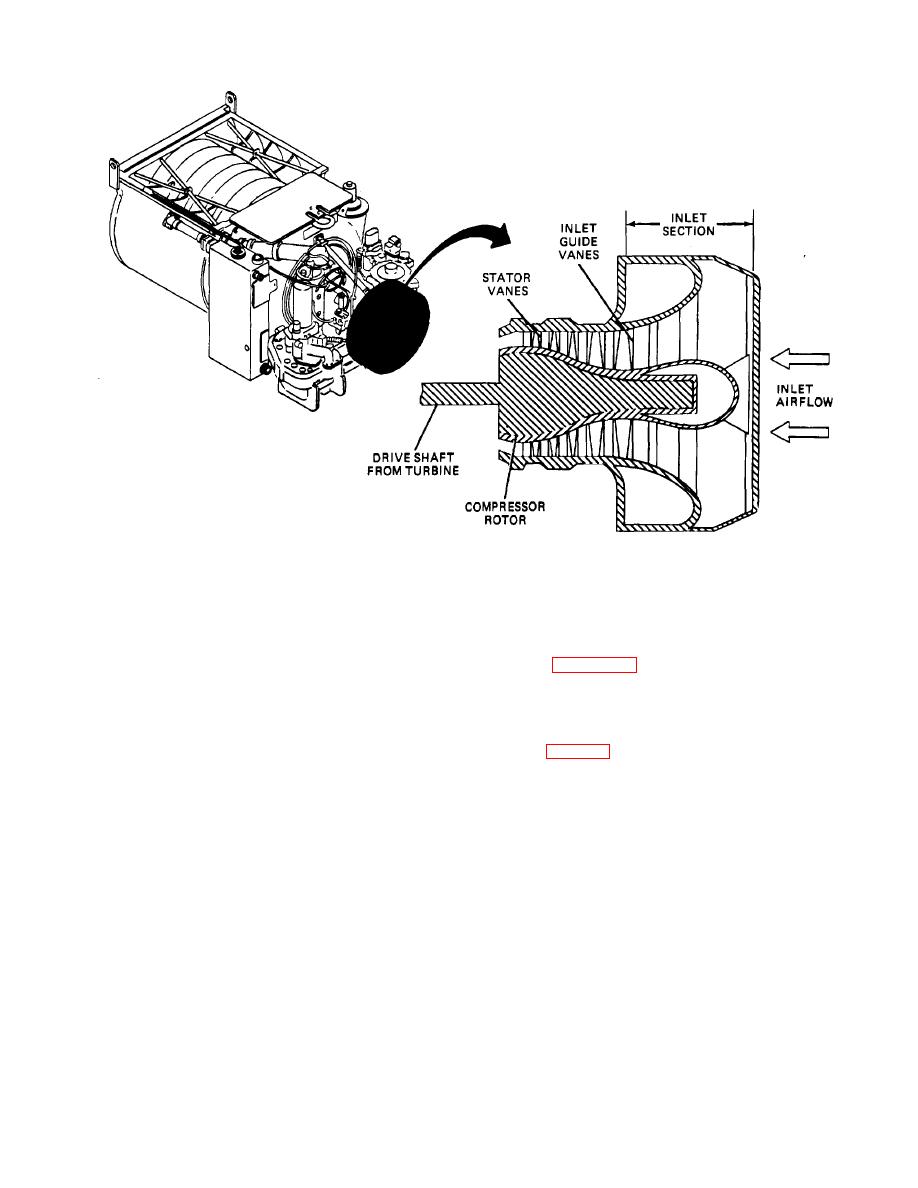

Figure 10-6. Air Inlet Section

and passed through each successive stage to complete

speed and flows through a set of diffuser vanes which

compression. The rotors increase velocity while the

decelerates the flow of air, converting high-velocity air to

stators decrease the velocity. The successive increases

high-pressure energy. The diffuser vanes also serve to

and decreases in velocity practically cancel each other,

straighten airflow. A typical centrifugal compressor is

with a result that the velocity, as the air leaves the

shown in figure 10-8. Centrifugal compressors achieve

compressor, is usually slightly greater than the velocity of

efficiency ratings of 78 to 84 percent and compression

the air at the entrance to the compressor. As the

ratios of approximately 5:1.

pressure is built up by successive sets of rotors and

stators, less and less volume is required. Thus, the

10-10.

Combustion Chamber.

The combustion

volume within the compressor is decreased gradually. At

chamber (fig. 10-9) is designed to burn a mixture of fuel

the exit of the compressor, a diffuser section within the

and air, and to deliver the resulting gases to the turbine

engine adds the final touch to the compression process

at a temperature that will not exceed the allowable limits

by decreasing again the velocity and increasing the static

at the turbine inlet. The chamber, within a very limited

pressure just before the air enters the engine burner

space, must add sufficient heat energy to the gases

section.

passing through the engine. This accelerates their mass

enough to produce the desired power for the turbine

b.

Centrifugal Compressors.

This type of

section. Combustion chambers are built in a number of

compressor consists of two main parts: an impeller and a

different designs. The construction is such that less than

diffuser. Centrifugal compressors operate by taking in

one-third of the total volume of air entering the chamber

air near the hub of the impeller and accelerating it

is permitted to mix with the fuel. The remaining air is

outward by centrifugal action. The impeller vanes guide

used downstream to cool the combustor surfaces, and to

the air toward the outer circumference of the

mix with and cool the burned gases before they enter the

compressor, building up the velocity by means of the

turbines.

high rotational speed of the impeller. Air leaves the

TA233508

impeller at high

10-7

|

||

|

||